Rapid production of products is the common goal pursued by colleagues in the manufacturing industry. Cemented carbide saw blades have low value, so production efficiency is particularly important for saw blade manufacturers. The grinding process occupies about half of the time in the saw blade production process, so how to improve the production efficiency of the saw blade grinding process is crucial for saw blade manufacturers.

The grinding process is divided into two processes: 1. The grinding process of contact between the grinding wheel and the workpiece; 2. Auxiliary time; The efficiency of the grinding process of contact between the grinding wheel and the workpiece can be improved by speeding up the cutting speed, but this also brings the disadvantage of accelerated grinding wheel wear, increasing the risk of rapid changes in workpiece size and increasing the number of grinding wheel replacements. Shortening unnecessary auxiliary time will provide more room for improving efficiency.

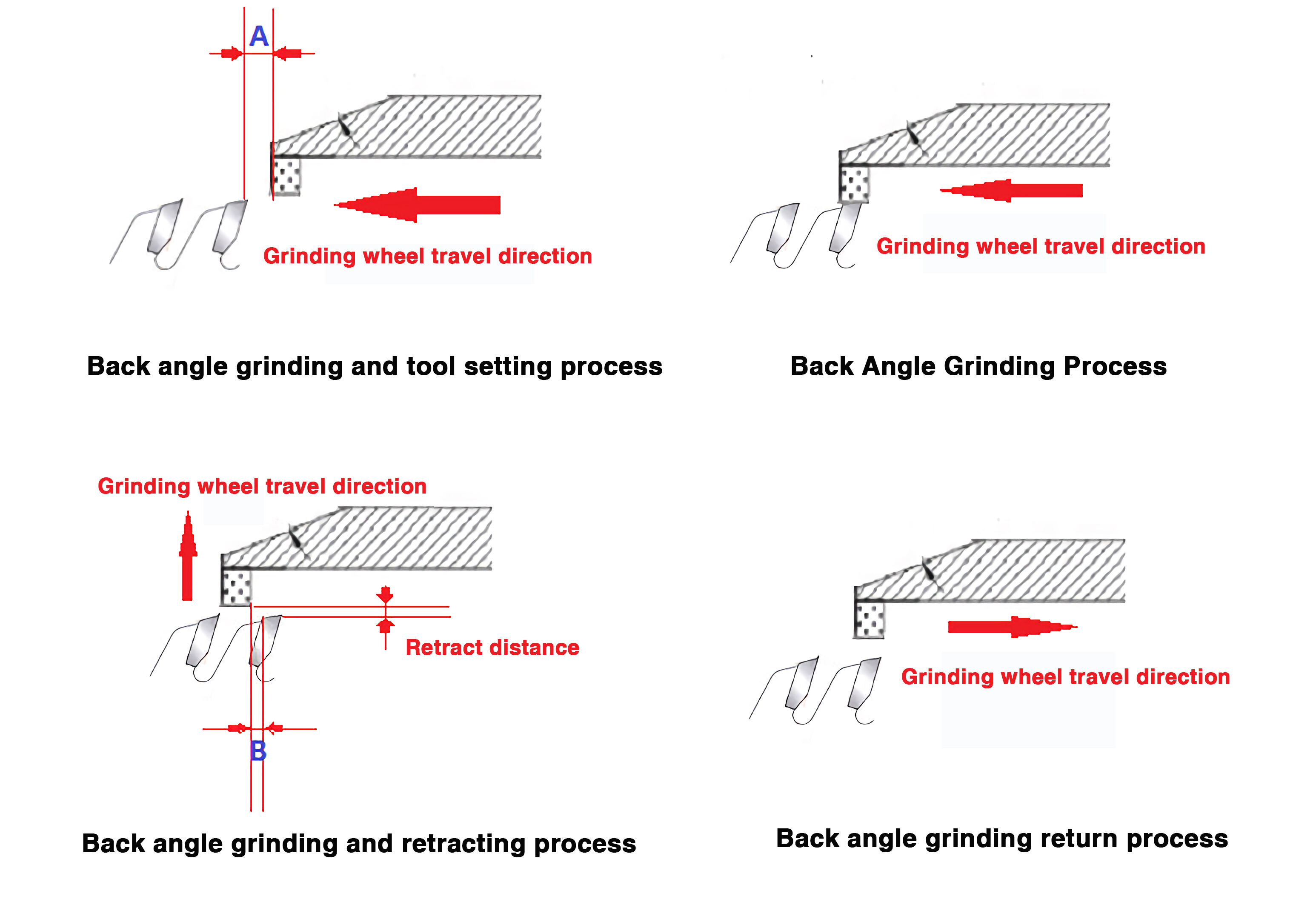

We use the back angle grinding of saw blades to illustrate how to improve the efficiency of saw blade grinding. The back angle grinding of saw blades is divided into the following four steps:

During the tool setting process: fast tool feeding is changed to slow tool feeding, where A = about 2 mm;

Common errors: A is too long, especially in the process of sparse tooth grinding, which seriously affects the grinding efficiency; A is too short, causing the grinding wheel to hit the workpiece before reaching the set speed, or even when the tool is fast, it hits the workpiece, resulting in serious wear of the grinding wheel.

Common problems in the grinding process: Too slow tool feeding speed affects the grinding efficiency; Too fast tool feeding speed leads to 1. The blade is fuzzy; 2. The grinding wheel is worn out quickly; 3. The saw blade accuracy is reduced; 4. The blade edge is broken (not sharp).

Determination of tool feeding speed: tool feeding speed (mm/s) X tool head width (mm) ≈ 10~15. For example: the tool feeding speed of 305X96TX3.2 = 10/3.2 = 3~3.5mm/s.

The length of the entire tool travel ≈ A + blade thickness + B + grinding wheel width = 2 + 3 + 2 + 5 = 12mm

The action of grinding each tooth = gear shifting + fast feed + slow feed + grinding + retracting + return; time = 1.0 + 0.5 + 0.5 + 3.5 + 0.5 + 1 = 7 seconds / tooth

Take 305X96T as an example: the overall grinding time is about 7X96 seconds = 672 seconds = 11.2 minutes

The way to speed up is:

1. Minimize the length of A and B.

2. Increase the feed speed in the four processes of gear shifting, fast feed, retracting, and return.

The above is an example of grinding the back angle to analyze how to improve the grinding efficiency. By analogy, the side and front angle can improve the efficiency of the entire grinding process through the above methods.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy