How to Extend Diamond/CBN Wheel Life to Reduce Replacement Costs? Diamond and CBN wheels play a pivotal role in precision grinding, cutting, and finishing activities in any of the industries such as manufacturing, aerospace, and automotive. They are ...

VIEW MORE

Grinding is a process that is expensive and causes work piece burning every time it is used in precision manufacturing. It undermines surface integrity, causes metallurgical damages and rejects. To users of superabrasive wheels, it is important to kn...

VIEW MORE

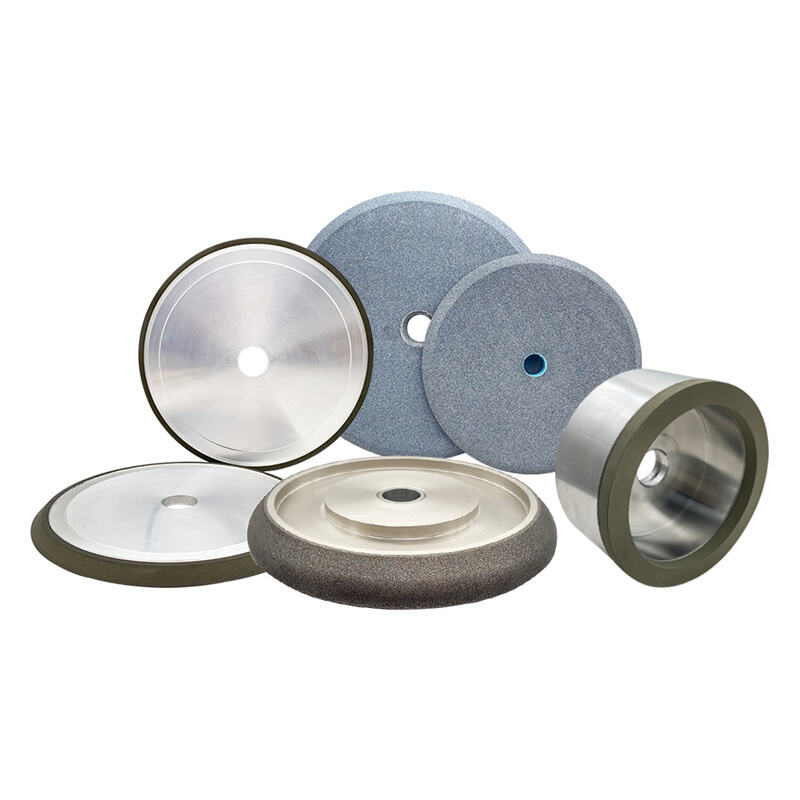

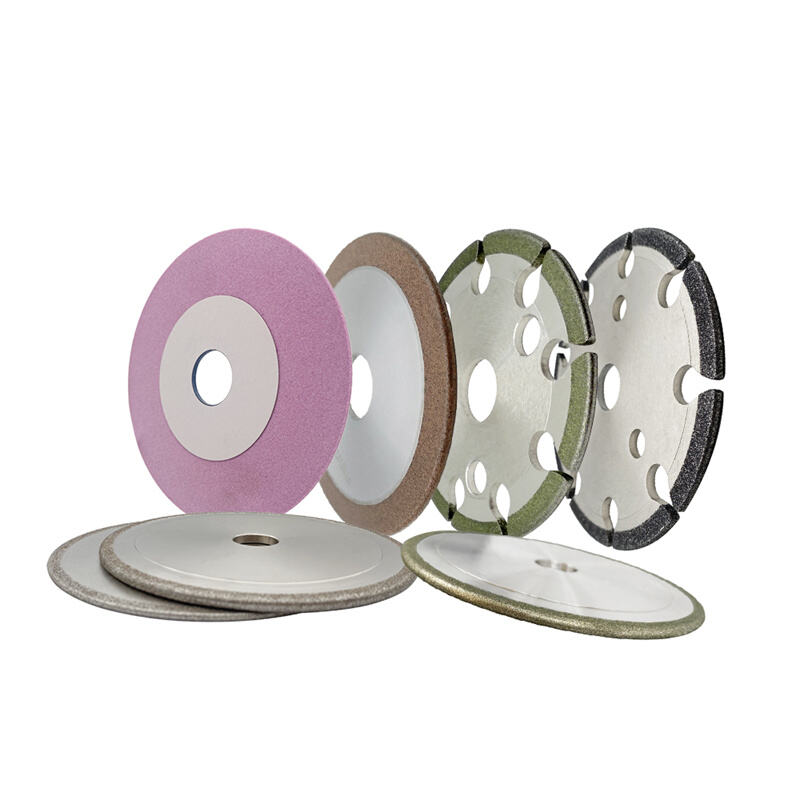

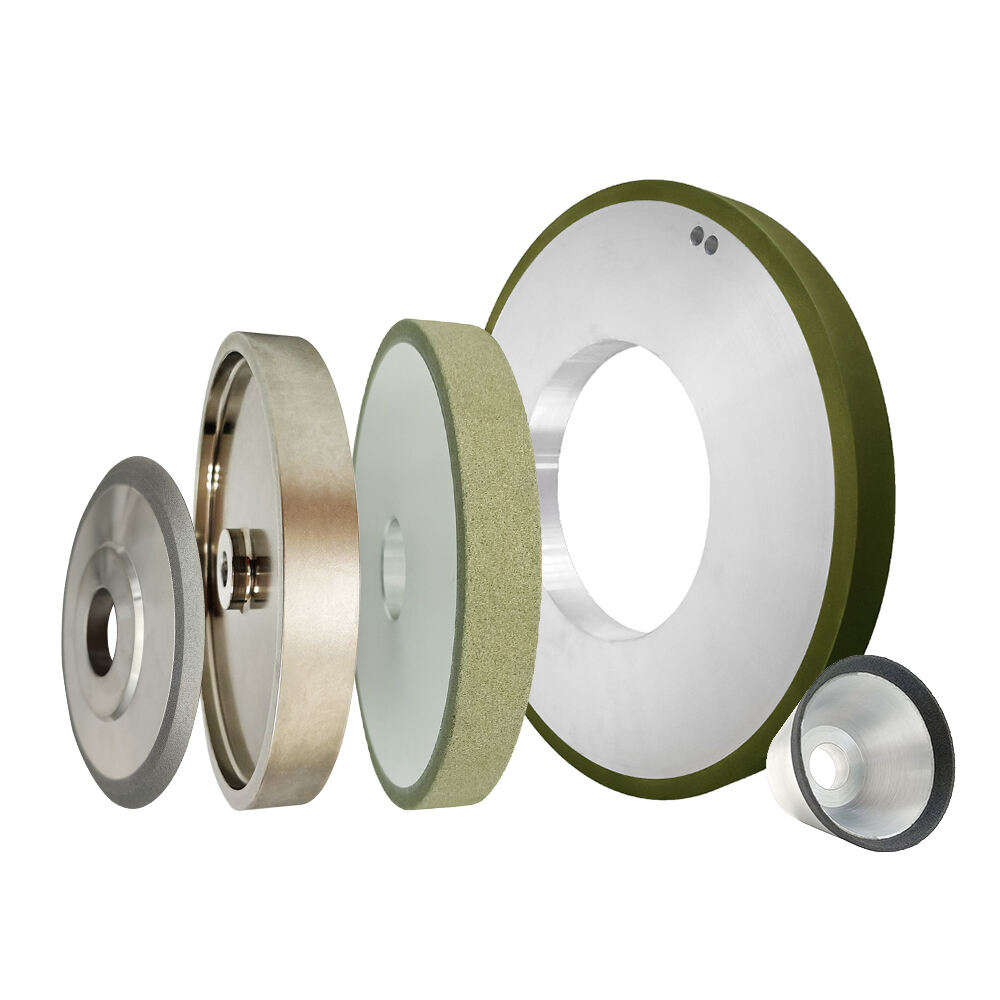

Diamond and Cubic Boron Nitride (CBN) wheels are considered the top of the world in relation to their performance in the sphere of precision grinding and cutting tools. We, Zhengzhou Ruizuan Diamond Tool Co., Ltd., are engaged in the manufacture of t...

VIEW MORE

Diamond and CBN wheels are major investments in high accuracy grinding. They perform outstandingly on hard and abrasive materials until they do not. Wheel chipping is one of the most irritating and expensive problems that users have to deal with. Suc...

VIEW MORE

In the modern competitive world of manufacturing and precision grinding, all the decisions made during operations should be explained by a definite return on investment (ROI). The selection of the correct abrasive tool in the job is one of the most i...

VIEW MORE

In investment in high performance diamond or CBN wheels, cutting efficiency is the most important aspect to maintain. Dressing is also a major aspect of this maintenance procedure that frees the wheel and re-sharpens it. To the professionals and the ...

VIEW MORE

To any expert in the grinding and precision machining market, Diamond and CBN wheel is a big investment in quality and performance. We realize at Zhengzhou Ruizuan Diamond Tool Co., Ltd. that we cannot stop safeguarding this investment as soon as the...

VIEW MORE

To get quality and efficiency, it is better to maintain your grinding activities at the maximum level of performance. The dressing of the wheel is one of the most significant maintenance jobs making the wheel be trued and possessing its cutting capac...

VIEW MORE

In precision grinding, especially of hard materials such as carbides, the choice of abrasive wheel is very important in determining the best efficiency, finish and the cost-effectiveness of the process. Diamond and CBN (Cubic Boron Nitride) wheels ar...

VIEW MORE

Where the finish of the surface in precision grinding is to be taken to the highest perfection, the question of the abrasive wheel becomes critical. This high-performance arena is dominated by two superabrasive materials diamond and cubic boron nitri...

VIEW MORE

Knowing The Underlying Difference Diamond And CBN To know which wheel will last; we have to start by knowing the construction make and properties of both types. Diamond wheels contain synthetic diamond crystals, which are the hardest known material o...

VIEW MORE

When it comes to high-speed grinding and, precision machining, selecting the proper abrasive wheel is of the essence. Two of the most simulating materials in such domain are diamond and CBN. Although both are super — abrasives, they each have u...

VIEW MORECopyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy