Zhengzhou Ruizuan Diamond Tools, a renowned name in the abrasive tools industry, recently participated in the prestigious Offshore Technology Conference (OTC) 2025. Held from May 5th - 8th, 2025, at the NGR Park in Houston, Texas, USA, the OTC is the world's preeminent event for the offshore energy sector. With over 1,300 exhibitors from more than 100 countries and regions, the event provided an ideal platform for Ruizuan to display its cutting - edge products designed specifically for the oil industry at Booth No. 1974.

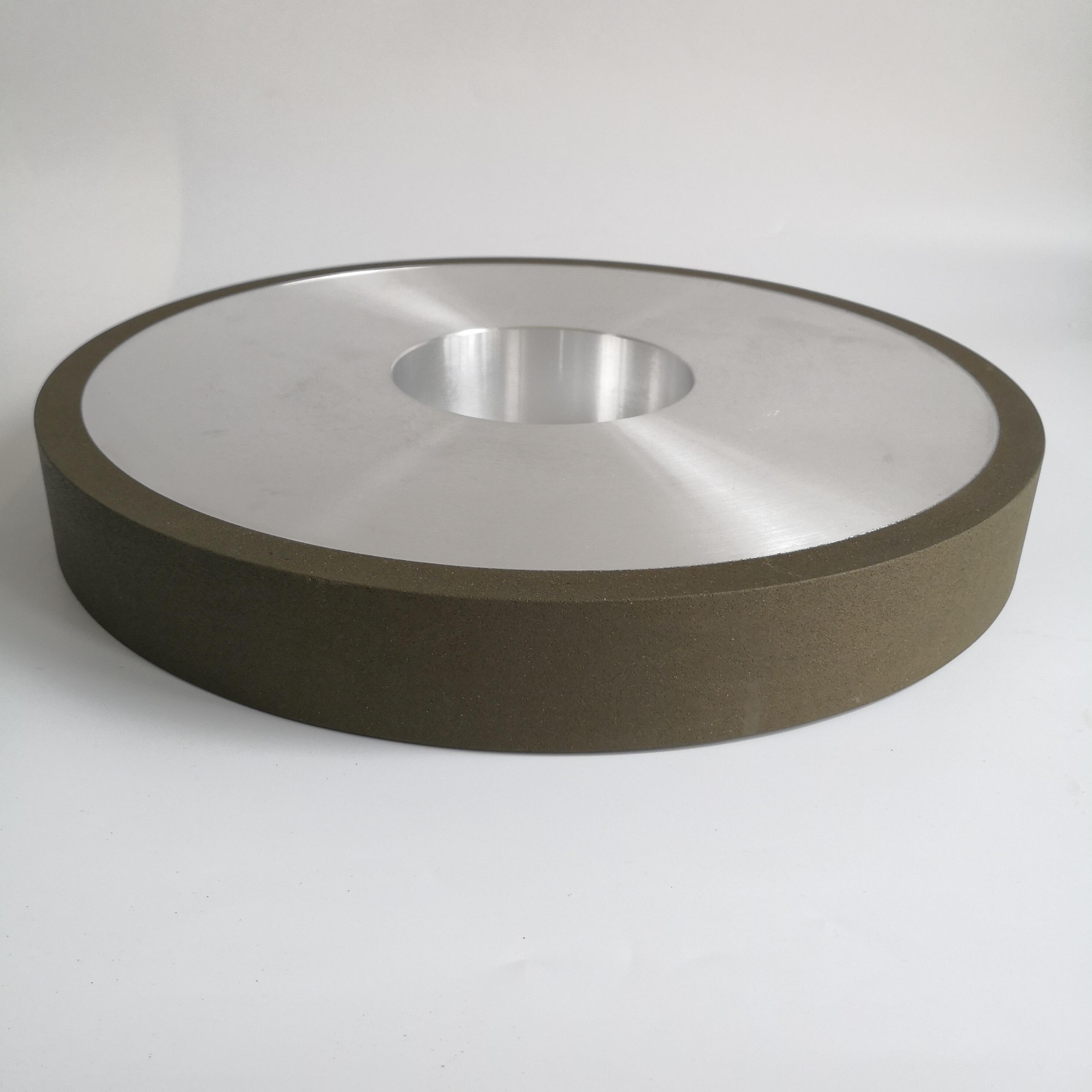

Displayed Products: 1A1 Resin - Bonded Diamond Wheels

Superior Grinding Performance

Our 1A1 resin - bonded diamond wheels are engineered with precision to meet the demanding requirements of the oil industry. The resin bond offers several advantages in this context. It provides excellent self - sharpening properties, ensuring that the wheel maintains its cutting efficiency throughout the grinding process. This is crucial when working with hard materials commonly found in oil - related components, such as carbide - tipped drill bits. The moderate abrasive - holding strength and wear - resistance of the resin bond make these wheels suitable for both roughing and finishing operations. During roughing, they can efficiently remove large amounts of material, while the fine - grit versions are perfect for achieving a smooth surface finish in the final stages of component manufacturing or refurbishment.

Custom - tailored for Oil - Industry Applications

In the oil and gas sector, components often need to withstand extreme conditions, including high pressures, corrosive environments, and abrasive wear. Our 1A1 resin - bonded diamond wheels are designed to grind materials that are used to manufacture parts like valves, pumps, and drill bits with high precision. For example, when grinding carbide - based components, the diamond - impregnated resin wheel can achieve a surface roughness of less than Ra 0.8μm, ensuring optimal performance and longevity of the final product. The porosity of the resin bond also allows for efficient chip evacuation, preventing clogging and reducing heat build - up, which is essential for maintaining the integrity of the workpiece and the wheel itself.

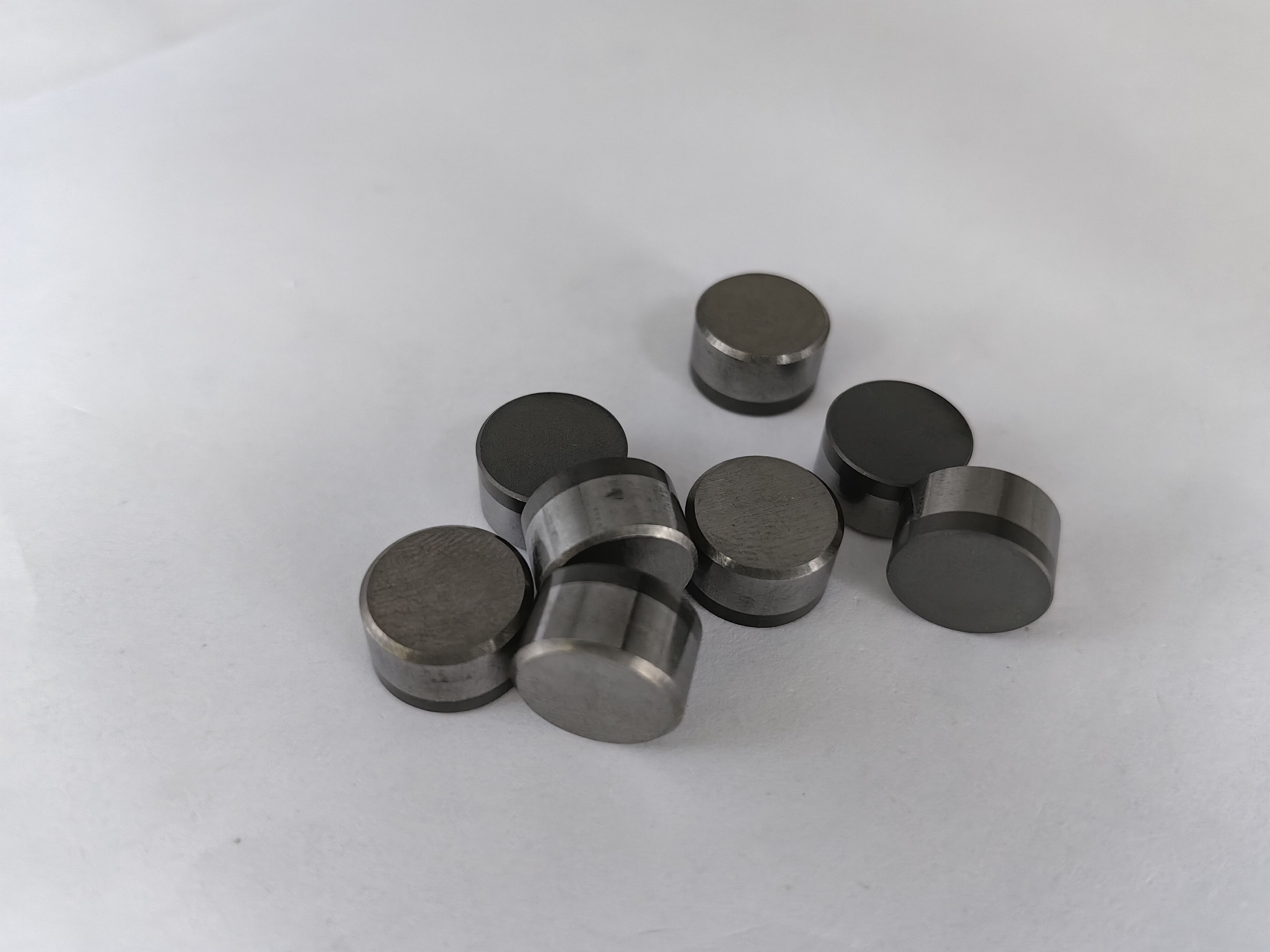

PDC Cutter: Precision - Engineered for Oil Drilling

Unmatched Hardness and Durability

Polycrystalline diamond compact (PDC) cutter are a staple in the oil drilling process, and Ruizuan's offerings stand out in the market. Our PDC cutter are manufactured using high - quality diamond grains sintered onto a tough carbide substrate. The diamond layer provides exceptional hardness, second only to natural diamond, which enables the blades to cut through the hardest rock formations encountered during oil exploration and production. The carbide substrate, on the other hand, offers excellent toughness, ensuring that the blade can withstand the high impact forces and vibrations associated with drilling operations.

Advanced Manufacturing Technology

At Ruizuan, we employ state - of - the - art manufacturing techniques to produce PDC cutter with precise geometries. The diamond layer is carefully engineered to have a uniform thickness and grain distribution, which maximizes the cutting efficiency and extends the blade's lifespan. Our PDC cutter can maintain a consistent cutting edge for up to 30% longer than some of the competing products in the market, reducing the frequency of blade replacements and minimizing downtime in drilling operations. Additionally, the unique design of our PDC cutter allows for better heat dissipation, which is crucial when drilling at high speeds, as it helps to prevent thermal damage to the diamond layer and the carbide substrate.

During the four - day event, our booth attracted a significant number of industry professionals, including oil and gas company representatives, drilling contractors, and equipment manufacturers. Our team of experts was on - hand to provide in - depth technical information about our products, answer questions, and discuss potential applications. We had numerous productive conversations with companies looking to improve the efficiency and performance of their drilling and component - manufacturing processes. Many of them were particularly interested in the cost - effectiveness and reliability of our 1A1 resin - bonded diamond wheels and PDC blades, as these factors directly impact their bottom line.

The OTC 2025 provided an opportunity for Ruizuan to showcase its decades - long expertise in the field of diamond - based abrasive tools. Our participation in this global event not only enhanced our brand visibility but also reaffirmed our position as a reliable and innovative supplier in the oil - industry value chain. By demonstrating the superior quality and performance of our products, we were able to build new business relationships and strengthen existing ones. We received several inquiries for custom - made products tailored to specific customer requirements, highlighting the flexibility and adaptability of our manufacturing capabilities.

Zhengzhou Ruizuan Diamond Tools' participation in OTC 2025 was a resounding success. The exposure to a global audience, the opportunity to showcase our advanced 1A1 resin - bonded diamond wheels and PDC cutter, and the interactions with industry leaders have all contributed to our growth and development in the oil - industry market. We look forward to leveraging the connections made at the event and continuing to provide high - quality, innovative products to meet the evolving needs of the oil and gas sector.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy