Auto processing wheels include – Vitrified cbn wheel for crankshaft / camshaft – Resin cbn wheel for flywheel – Diamond / cbn wheel for valve / valve seat – Brake pad grinding wheel - Bearing grinding wheel - Diamond Grinding Stick Stones for Ball vlave

Contact Us

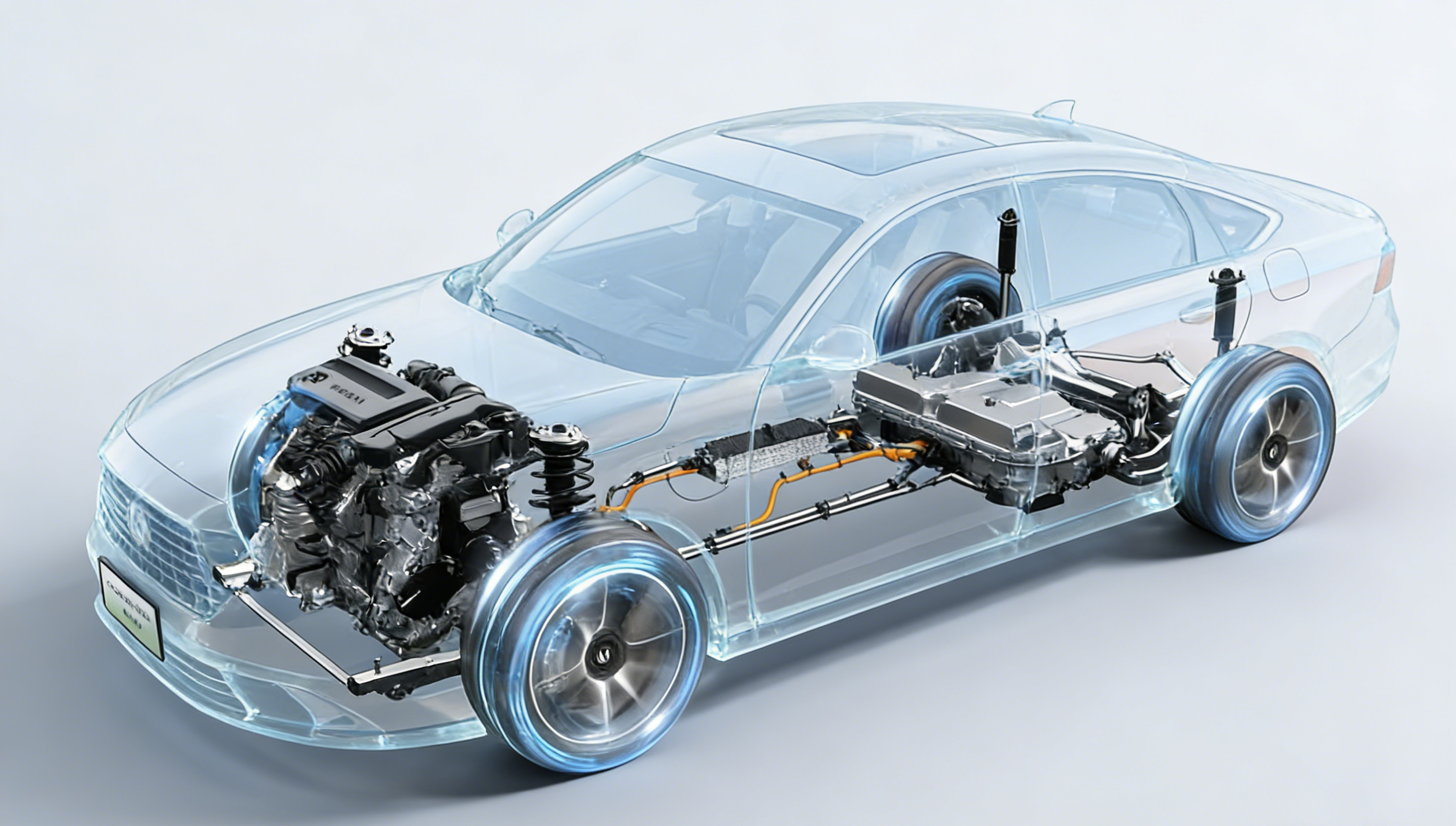

System Solutions from REZZ for Auto Processing

Improving the surface finish and dimensional accuracy of critical vehicle components, such as engine parts, transmission gears, steering system, and brakes is crucial for ensuring the safe and reliable operation of the vehicle. This makes precision grinding an essential process in the manufacturing of high-quality automotive components.

REZZ can provide you superabrasive tools for machining engine, chassis and transmission components in automotive industry .The processed auto parts include, crankshaft, camshaft, connecting rod, transmission case, gearbox shaft, clutch housing, brake disc and drum, cylinder block, cylinder head, aluminum wheel and pressure, etc

REZZ supports the automotive industry with superabrasive products , such as CBN grinding wheels for crankshaft and camshaft grinding, vitrified cbn slotting wheel, resin bond grinding disc for auto parts,diamond dressing rolls, CBN internal grinding wheel, diamond CBN honing stone, electroplated metal CBN grinding wheel for crankshaft, CBN grinding wheel for valve, resin bond grinding wheel for brake plate processing, diamond CBN grinding wheel for bearing, etc

Engine Part Grinding

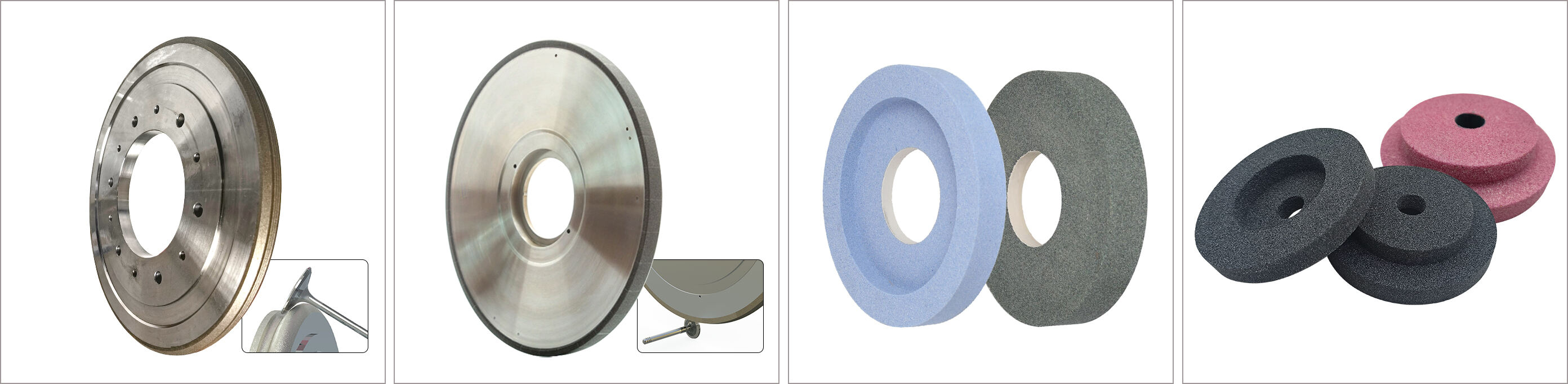

* Vitrifed CBN Wheel for Crankshaft / Camshaft

REZZ can provide vitrified CBN grinding wheel and vitrified aluminium oxide grinding wheel.

Crankshaft and Camshaft are usually made of cast iron, grey iron, forged steel and powder metallurgy. REZZ crankshaft camshaft wheels can be used for roughness grinding, finishing grinding and large feed grinding. Normal speed is 80-160m/s. Wheels can be single, double, group used, A series of vitrified bond can be provided. Vitrified CBN grinding wheel is suitable for high efficient, heavy grinding of crankshaft pin grinding, journal grinding.

Applicable Machine Brand: JUNKER, SCHAUDT, LANDIS, TOYODA.

| Parameters | |||

| Model | D(mm) | H/U(mm) | T(mm) |

| 1A1 | 300-650 | 5-10 | 10-50 |

| 3A1 / 14A1 | 300-650 | 5-10 | 10-50 |

| 3F1 | 300-650 | 5-10 | 10-50 |

| 14LL1 | 300-650 | 5-10 | 10-50 |

* Resin Bond CBN Wheel for Flywheel

Our 6 inch CBN Flywheel Grinding wheel is the standard wheel found on most flywheel grinding machines. These wheels are compatible with DCM Tech, Kansas Instruments, Kwik-Way, Peterson, RMC, Rogers, Van Norman, Winona Van Norman and other Flywheel Grinding machines with 1-1/4" spindle arbors.

| Parameters | |||||

| Model | D(mm) | T(mm) | H(mm) | U(mm) | X(mm) |

| 11V9 | 100 | 40 | 31.75 | 10 | 3 |

| 125 | 40 | 31.75 | 10 | 3 | |

| 150 | 45 | 31.75 | 10 | 3 | |

| Common Grit: D20 D46 D64 | |||||

Engine Valve Grinding

REZZ provide elcetroplated /vitrified / metal CBN grinding wheel Vitrified CBN grinding wheel can used for the main parts of valve include: Valve cut off grinding,valve shaft centerless grinding, valve head & seat grinding, valve groove & tip raduis grinding, valve stem end grinding and valve seat grinding.

* Valve Refacing Wheel

REZZ can provide vitrified CBN grinding wheel, vitrified aluminium oxide grinding wheel and silicon carbide grinding wheel.

Applicable Machine: SVSII-D series machines

* Valve Seat Grinding Wheel

Diamond grinding wheel -Grinding wheel angle:30°, 45°, 55°, 60° -Size: 18-66mm

Abrasive grinding wheel -Grinding wheel angle:0°, 30°, 45° -Size: 32mm, 33mm, 35mm, 36mm, 38mm, 41mm, 43mm, 44mm, 47mm, 51mm, 54mm, 57mm, 60mm.

Applicable Machine: Sioux Valve Seat Grinder, B&D valve grinding machine, Kwik-Way Valve Seat Grinder.

Brake Pad Grinding

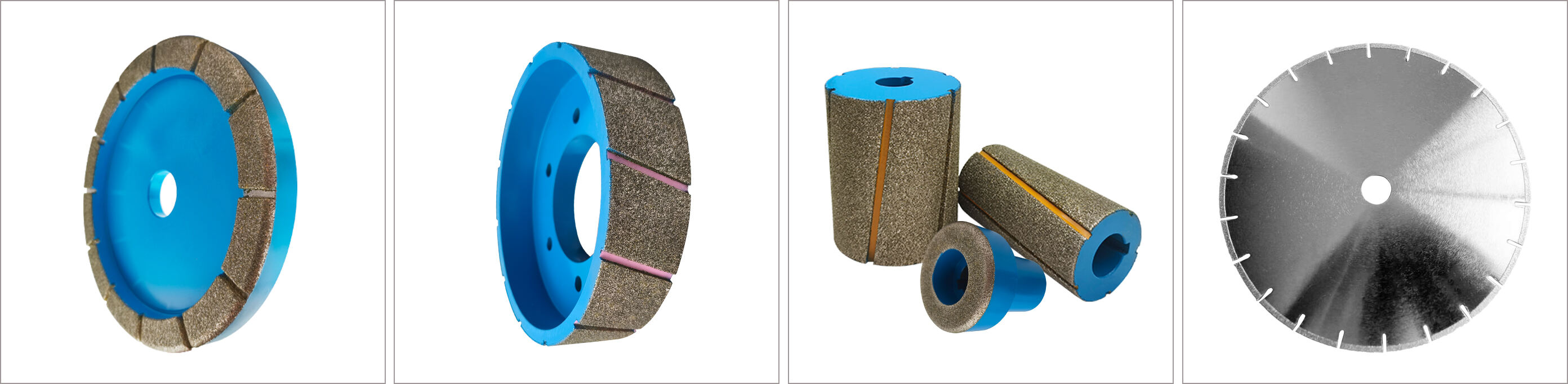

* Brake Pad Grinding Wheel

To ensure that brake discs achieve their optimum performance and thus, guarantee maximum safety, they must have the right thickness, parallelism and surface finish. Whether you are shaping, beveling, or chamfering brake pads, this wheel delivers consistent and precise results, enhancing efficiency and productivity.

Size: 200mm,250mm,300mm,customized

Grinding Method: Surface grinding, internal and external arc grinding, chamfering, grooving.

Applicable Machine: domestic Baiyun, Jilin Wanda, Qingdao Furui, Golden Phoenix and other brake pad grinders; foreign (COMEC, SANGSIN, BT, etc.)brake pad grinders and complete production lines

Fuel Injection Grinding

* Fuel Injection Technology

With decades of experience in the development and manufacturing of high precision superabrasive tools for fuel injection, REZZ has mastered the art of meeting strict surface quality and workpiece geometry requirements. Achieving these narrow tolerances can only be accomplished by matching a grinding and a dressing tool designed specifically for these applications. Prioritizing low grinding forces is paramount when machining long bores, and our innovative internal cooling tools are the benchmark in needle seat machining.

Workpiece: fuel injection bore, fuel injection seat.

Workpiece Material: 18CrNi8, GCr15, K340, 440c, 440J, 1538MV, 100Cr6, etc.

Applicable Machine: Studer S11, DL-GR7400

Gear Shaft Grinding

* Gear Shaft Grinding

This product is designed for the grinding of deep grooves in transmission shafts, drive shafts, steering gears, and other components.

In the quest for noise and fuel consumption reduction, the requirements for the geometry and finish of transmission and engine components are becoming increasingly stringent. Precision grinding plays a central role in meeting these demands, and Meister Abrasives' grinding and dressing tools play an essential part in achieving these high standards.

Bearing Grinding

* Bearing Grinding Wheel

REZZ can provide abrasive grinding wheel, resin diamond grinding wheel, vitrified diamond CBN double disc grinding wheel for lapping and polishing bearing outer ring or inner ring.

Applicable Machine: Wendt WBM, Viotoo, AMT, Stahli, Peter Wolters, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Speedfam, Kemet, Gardner and other brands.

* Diamond and CBN internal grinding wheel

REZZ offer a full range of abrasive tools including vitrified diamond and CBN, sintered corundum internal grinding wheel with shank and eithout shank for grinding the bores of inner rings and the machining of outer ring races, also used for high precision grindin ggear bore .

* Diamond dresser tool

| Dimensions | ||||||

| Grinding Method | Model | D(mm) | T(mm) | H(mm) | W(mm) | X(mm) |

| Surface grinding | 1A2, 2A2T, 6A2B | 300-1500 | / | / | 40-350 | 3-10 |

| Cylindrical grinding | 1A1, 3A1, 14A1 | 200-900 | 25.4-50.8 | 25.4-304.8 | / | 12.7-20 |

| Centerless grinding | 1A1, 6A1, 9A1 | 125-60 | 50-350 | 75-305 | 5-10 | |

| Internal grinding | 1A1, 1A8, 1A1W | 50.8-200 | 25.4 | As required | As required | |

| Profile grinding | As required | |||||

| Any nonstandard size and grits can customized.(tell me size or drawing is enough) | ||||||

Ball Valve Grinding

* Resin Bond Diamond Grinding Stick Stones

Common type grinding stones for carbon steel and stainless steel balls

Diamond type grinding stones for tungsten carbide coating balls

Applicable Machine: SAPORITI, CMXCNC, CAMINIX, DORY, Machine tools, indiaMART, KOPMC, etc.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy