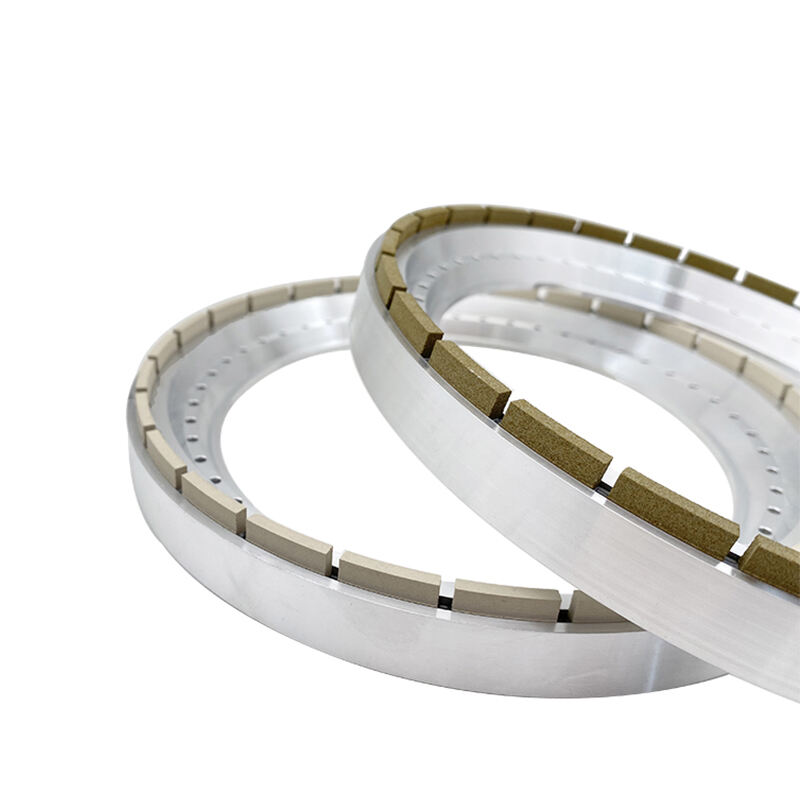

Now, when selecting the right Diamond Grinding wheel from REZZ for your carbide tools there are a few factors to consider. First, check the grit size. Grit size gives you an indication of how rough or smooth a wheel is. One coarse grit wheel is best suited for heavy grinding, and one fine grit wheel would be better for sharpening. Next, look at the bond type. It is the glue that holds the diamond particles together. Some are hard enough to be longer lasting, while softer ones may work better on certain materials. Also, consider the wheel's shape. Various shapes such as flat shape or cup shape can be used for different grinding processes. Just make sure you choose one that will work for your needs. Finally, you can consider the speed at which the wheel will be spun. Some wheels are better at high speeds while others are better at slow speeds. This will typically be on the item description or packaging. If you take the time to select a good one, it can give you good results when sharpening your diamond grinding wheel cup.

It is not always very easy to use these diamond grinders and therefore their users may find themselves facing some typical problems. One of the problems is overheating. The tool actually may run in a hot grinding operation and this heat can be damaging both to the tool and to the wheel. To avoid this, it is very important to cool the tool while grinding. You can run cool water over your beans or use other cooling ways

Another problem is wheel wear. The diamond particles will eventually become dulled and their grinding efficiency will decrease. Frequently checking the wheel for wear and replacing it when necessary is a good idea. Those who had difficulties with uneven grinding were also there. This happens if the wheel is not properly seated or there is uneven pressure. Another reason may be that the wheel is not correctly set up and forcing it into the dropouts or constantly applying pressure can also fix this. Lastly, there may be dust and dirt from the grinding process that can cause problems with visibility and use. A clean workspace and a dust collector can help prevent this. Knowing about these problems, users can appreciate the process of carbide tool sharpening on diamond angle grinder cup wheel from REZZ.

Apart from that, diamond grinding wheel is a better choice because it can help in giving a proper finish to the tools. If you are sharpening a tool, then the first thing to consider is making the tool sharp; however, it should also be a clean edge that you leave behind. REZZ grinding wheels have high, quality diamonds that are capable of doing this. They literally go through the material without stripping or damaging the surface of the tool, which happens to be one of the problems with other grinding wheels. Its glossy and smooth edge helps you make more accurate cuts, which is very significant for those who are doing detailed works

In summary, the main reason why diamond grinding wheels remain the best option for sharpening carbide tools is the combination of their long, lasting nature and high performance.

Diamond grinding wheels can sometimes be a bit tricky to work with, but these tips should help you fix most common grinding issues. A few users have complained about the wheel's rapid breakdown in some instances. When that happens, you really should check if the wheel is getting the proper treatment. Pressure that is just right with stringing. Besides, if you push harder than necessary, the diamonds will get worn out faster. REZZ's diamond grinding wheel for carbide tools a moderate and steady pressure ensures a longer life, don't hurry. On the other hand, if the wheel is still going through the material too fast, then you may consider adjusting the machine settings and see what you can change.

Overheating while sharpening is another frequent issue. Both the tool and the grinding wheel can be damaged by over-heating. In order that these injurious effects may be avoided, it is necessary to keep the tool and wheel cool. This can be achieved by wet grinding with water or coolant. REZZ grinding wheels are designed to take a bit of heat, but a little coolant will keep things at the right temperature. If overheating is a frequent problem, it could be because grinding speed is too high. The slower pace can help prevent heat, and also to make sure that everything is kept in good order.

We're committed to delivering the highest quality products and outstanding service. We implement rigorous quality control methods to make sure that each and every one of our grinding wheels is in line with industry standards. This provides our customers with peace of mind and reassurance. Our customer service team will be available at all times to assist and ensure that you have a smooth journey from order to delivery.

The research and development department at our company is continuously searching for new materials and processes to ensure we stay at the top of the industry in abrasives. We place great emphasis on sustainability and performance as well as providing efficient grinding solutions that can satisfy the ever-changing needs of our customers. We are your partner for accuracy, innovation and quality in all grinding applications.

REZZ is a manufacturer of grinding wheels since 2014, and we have a wealth of experience in supplying grinding wheel solutions. We provide a broad range of custom Diamond CBN grinding wheel services which help our industrial and manufacturing customers develop higher quality products and reduce their operating cost.

We recognize that each client has unique needs. We offer a variety of customizable and custom grinding wheel solutions tailored to specific needs. In close collaboration with our clients, we create customized products that improve their effectiveness in operation, focusing on satisfaction of the customer.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy