Ceramic abrasive wheels are an essential tool in a number of industries. They are used to shape, grind or polish materials such as metal and stone. These are fabricated out of a special type of ceramic that is extremely hard and long lasting. That’s also why they’re not easily broken when cutting through harder materials. Companies like REZZ produce of high quality ceramic grinding wheels for the professional and hobbyist. Knowing how to select the best Ceramic Grinding Wheel is also a great solution for workers who need to be successful in all of their grinding projects

For anyone in the need of a ceramic grinding wheel, it is best to start by considering what it will use for. First, think about the type of product you will be grinding. Various materials also need various wheels. For instance, if you are working with metal, you may want a wheel actually designed for that. If you were grinding stone, I would say you might need a different wheel. Next, check the wheel grit size. The grit size of a grinding wheel is the degree of roughness or smoothness which effects how quickly material, be it metal or otherwise, will be removed from the complete work. The finer grit wheel will give a smoother finish, the coarser grit will remove diamond grinding wheel for carbide tools material more quickly. It’s also the bond type of the wheel that needs to be checked. This is what holds the abrasive together. For heavy manhole cutting, hoarding cutoff and wharfdeck work the harder bond is probably better. Alternatively, though, a more supple bond could be better for lighter duty. Another thing to keep in mind is the wheel size. Bigger wheels may be able to grind more substance at one time but it won’t let you do the small kinds of work. Make sure the wheel fits your grinder as well! Finally, there’s the speed rating to consider. Each wheel has a maximum speed that it can cope with, so make sure that this is compatible with your machine. By taking all these factors into account, you will be able to make the right selection of ceramic grinding wheels for your application.

Quality ceramics grinding wheel at wholesale prices is a hard thing to find, however, it can be done in a few different ways. First check out local suppliers and industrial supply shops. Another good place to look would be tool supply places [local] that sell or rent grinders they often have a variety of grinding wheels, and you might even get discounts if you buy in bulk. Or you could do some online hunting. You can find websites dedicated to industrial tools, such as REZZ. They may have a fantastic answer, particularly if you’re on their newsletter or promotion list. Also, participate in trade shows or industry events. They’re also great places to meet manufacturers and suppliers who may have access to unique wholesale prices. Make sure you ask for samples as well! Testing out a wheel before ordering a bunch is smart. Be sure to read reviews and talk with other users. This way, you can steer clear of subpar diamond lapidary wheels products. Networking with others in your industry can also give you a tip or lead on where to find the best deals. By considering these choices here, you will be able to find high-quality ceramic grinding wheels at a budget-friendly price

Ceramic grinding wheels are integral to the business of a variety of enterprises including manufacturing and metalworking. These are made of a really hard material called ceramic that is super strong and ideal for grinding. One of the great things about ceramic grind wheels is they make workers jobs easier, and get done faster. When workers use these wheels, they can shape and smooth metal parts in a hurry. This allows companies to manufacture more products in less time and that’s good for business. When employees can complete their responsibilities more quickly, that could result in lower manufacturing costs. That’s because companies don’t need to put as many hours into each job.

What's more, REZZ ceramic wheels outlong others. What that means of course is business don’t have to buy new wheels anywhere near as often, eventually saving them money. A long-life grinding wheel not only reduces waste. This can enable companies to use their resources more wisely; for the environment, this is also a plus. An added benefit when grinding these mopeds is that ceramic wheels like REZZ will produce less heat. This is significant because excess heat can ruin the metal parts being worked. Keeping the diamond cup disc temperature down, these wheels keep your products fresh. Ultimately, ceramic grinding wheels help businesses to work smarter and save money while producing high-quality items.

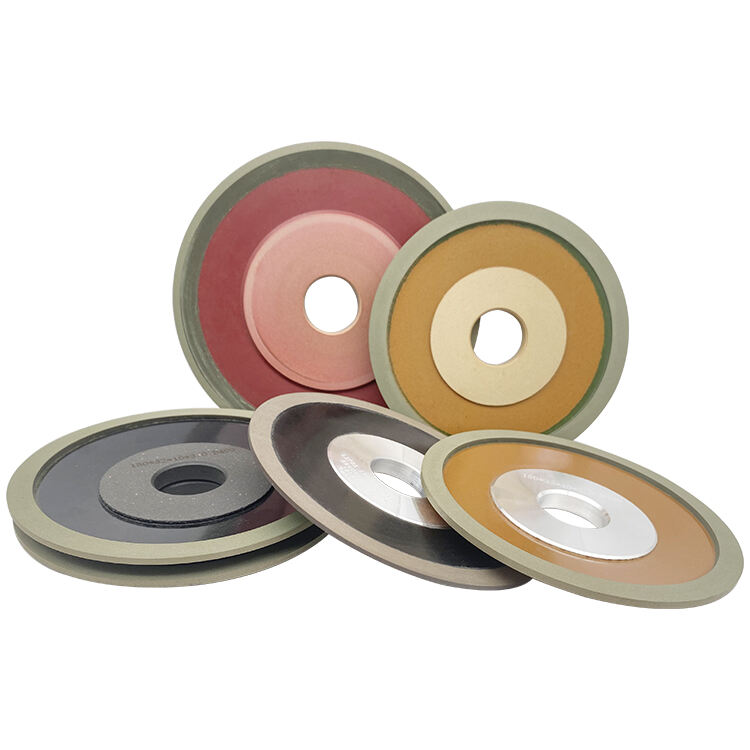

REZZ is constantly looking for ways to enhance its ceramic grinding wheels. The company is dedicated to research and development of products in order to make products that cater to the needs of modern industries. Newer models also include better airflow during grinding. This is necessary so as to cool the wheel and material being worked on, thus preventing damage. Moreover, with the development of grinding wheels of various dimensions and shapes they become universal. Today, they can be employed for dozens of resin bond grinding wheel tasks from small precision work to bigger grinding jobs. With this new technology added to ceramic grinding wheels becomes even more productive and effective.

A scratched wheel will lose its brilliance, and could even become unsafe after being repaired. In addition, grinding needs to be done with the proper speed and pressure. The wheel can become worn if it spins too quickly or too slowly. For best results, REZZ rcommends following manufacturer's instructions.

The research and development department at our company is continuously searching for new materials and processes to ensure we stay at the top of the industry in abrasives. We place great emphasis on sustainability and performance as well as providing efficient grinding solutions that can satisfy the ever-changing needs of our customers. We are your partner for accuracy, innovation and quality in all grinding applications.

REZZ is an experienced grinding wheel manufacturing company that has been offering grinding wheel processing solutions since. We provide a broad range of customized Diamond CBN grinding wheel services which help our manufacturing and industrial customers develop higher quality products and reduce their operating cost.

Every client has their own specific requirements. So, we provide customizable and personalized grinding wheel solutions that are tailored to specific requirements. Collaborating closely with clients to develop custom products that enhance their effectiveness in operation, focusing on satisfaction of the customer.

We're committed to providing superior quality products at the top of the line and unparalleled service. Our rigorous quality control processes make sure that each and every grinding wheel meets the most stringent standards in the industry, supplying our customers with trust and security. Our customer service team is always available with a smooth order-to-delivery experience.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy