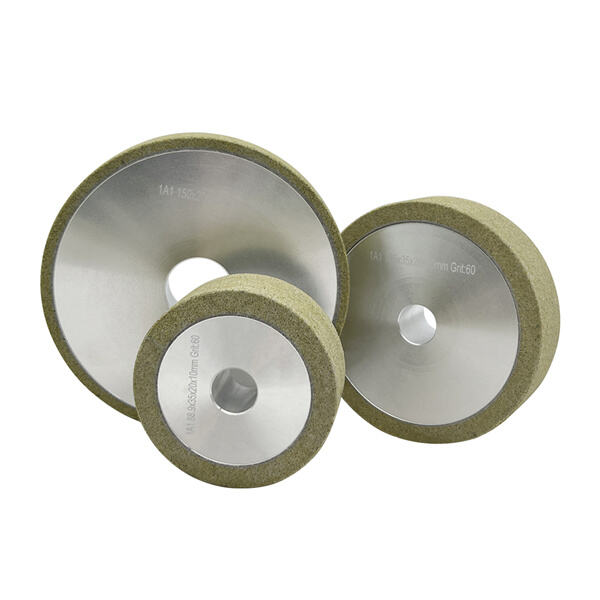

Have you ever thought about why some grinding discs perform better than others? The answer lies in the materials that went into them. You can also use ceramics to get your discs to grind better; this will allow you to work with more accuracy and speed. Understanding what makes these discs unique and how they can enhance your work is crucial.

Hard and durable — Ceramic grinding disc Since ceramic is a very strong and tough material, ceramic grinding wheels are the same. This material is meant to withstand a great deal of friction, so it can grind hard substances, such as metal and concrete, without breaking or dulling. Ceramics are sharper and preform better than some other materials. This means you won't have to replace them as often, saving you time and money as you work.

Ceramic discs also tend to grind more quickly and generate less heat. This matters because it allows you to work for longer without needing to stop to cool the machine down. That saves a lot of time and makes your job quicker and easier when you don't need to stop all the time! You complete work faster and get more done.

Historically, grinding discs were often manufactured from materials such as aluminum oxide or silicon carbide. While these materials served their purpose, they also possessed shortcomings. But this situation is now a thing of the past, with the revolutionary technology of ceramic grinding discs taking the grinding industry by storm.

One major benefit of ceramics is that they can grind dry. That means they can sever matter without requiring oil or water. That is a huge benefit as it helps with keeping the job cleaner and therefore allows for the materials to be used sooner. There is no additional cleaning up after your work, saving you time and energy.

And if you deal with materials that require frictionless surfaces, ceramics is what you need. They readily are able to mill media such as glass and ceramics, providing the correct output with minimal wear. This means that you can achieve beautiful and professional finishes with very little effort.

Do you know what else creates fewer sparks when you use them? Ceramics. Thus, they are a safer risk to deal with. Because they are not electrically conductive, you can use them with a greater sense of safety. This minimizes the risk of accidents and creates a safer working environment for you.

We're dedicated to providing superior quality products at the top of the line and unparalleled service. Our stringent quality assurance processes ensure that every grinding wheel meets the most stringent standards in the industry, supplying our customers with trust and peace of mind. Our customer service staff is ready to help to ensure a smooth ordering experience.

Our committed research and development staff continuously studies new materials and processes and puts us at the top of the market for abrasives. We place a premium on the performance and sustainability of our products as well as offering efficient grinding solutions that can keep up with the demands of our clients. We are your trusted partner for accuracy, innovation and top-quality grinding processes.

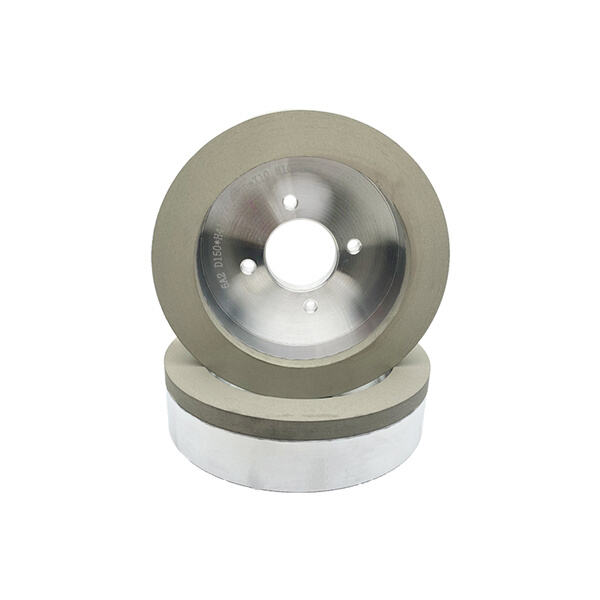

Every client has their own specific requirements. So, we provide customizable and personalized grinding wheel solutions that are tailored to specific requirements. Collaborating closely with clients to develop custom products that enhance their effectiveness in operation, focusing on satisfaction of the customer.

REZZ is an experienced grinding wheel manufacturer that has been offering grinding wheel processing services since 2014. Our custom Diamond CBN Grinding Wheel Services aid our manufacturing and industrial clients design more efficient products and decrease their operating costs.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy