In the realm of CNC machining, the precision and performance of cutting tools are paramount. Selecting the right grinding wheel for sharpening and reconditioning CNC cutting tools is a critical decision that directly impacts machining accuracy, tool lifespan, and production efficiency. At Zhengzhou Ruizuan Diamond Tools, with our extensive expertise in abrasive solutions, we're here to guide you through the process, focusing on the applications and unique advantages of resin - bonded diamond and hybrid - bonded diamond CNC grinding wheels.

The Vast Application Scope of CNC Grinding Wheels

CNC grinding wheels are employed across a wide spectrum of industries and machining tasks:

Aerospace Industry: Used for grinding high - performance alloys like titanium and Inconel in the production of turbine blades, engine components, and structural parts. Precision is crucial here, as even minute inaccuracies can compromise the safety and efficiency of aircraft.

Automotive Manufacturing: Essential for sharpening cutting tools used in machining engine parts, transmission components, and automotive molds. The need for high - volume production with consistent quality makes the selection of the right grinding wheel vital.

Medical Device Production: In the fabrication of surgical instruments, implants, and dental tools, where extreme precision and surface finish requirements are non - negotiable. CNC grinding wheels help achieve the tight tolerances and smooth surfaces necessary for these life - saving and enhancing devices.

Tool and Die Making: For shaping and sharpening complex cutting tools and dies used in various manufacturing processes. The ability to create intricate geometries with high accuracy is a key requirement in this field.

Electronics Industry: Used in the production of semiconductor components and micro - machining operations, where nanometer - level precision is often demanded.

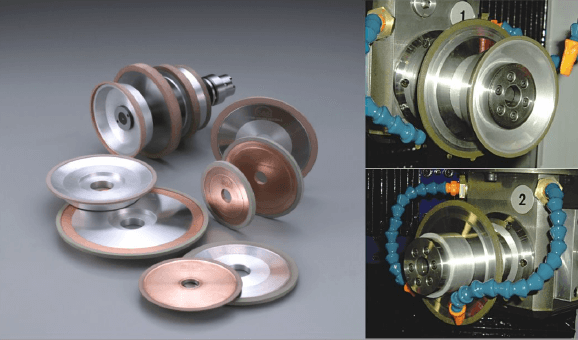

Resin - Bonded Diamond CNC Grinding Wheels: The Epitome of Flexibility and Precision

Key Characteristics

Resin - bonded diamond CNC grinding wheels are renowned for their unique combination of properties:

Flexibility: The resin bond provides a certain degree of elasticity, allowing the wheel to adapt to the shape of the workpiece during grinding. This flexibility reduces the risk of chipping and cracking, especially when working with brittle materials or complex geometries.

Low Heat Generation: Resin bonds have relatively low thermal conductivity, minimizing heat transfer to the workpiece. This is of utmost importance when grinding heat - sensitive materials such as high - speed steel (HSS) cutting tools, as excessive heat can alter the material's properties and degrade the tool's performance.

Self - Sharpening Property: As the wheel grinds, the resin bond gradually wears away, exposing fresh diamond abrasive grains. This continuous self - sharpening mechanism ensures a consistent cutting action throughout the wheel's life, maintaining machining accuracy and surface finish.

Ideal Applications

Fine Grinding and Finishing: Resin - bonded diamond wheels are excellent for achieving high - precision surface finishes, making them ideal for the final stages of CNC cutting tool sharpening. They can produce surface roughness values as low as Ra 0.2μm, ensuring that the cutting edges are smooth and sharp, which is essential for reducing friction and enhancing tool life.

Grinding of Hard and Brittle Materials: Materials like carbide, ceramic, and glass can be efficiently ground with resin - bonded diamond wheels. The diamond abrasive's extreme hardness combined with the resin bond's flexibility allows for precise material removal without causing excessive damage to the workpiece.

Ruizuan's Edge

Our resin - bonded diamond CNC grinding wheels are manufactured using advanced formulations and state - of - the - art production techniques. We carefully select high - quality diamond grains with consistent size and shape distribution, ensuring optimal cutting performance. Additionally, our proprietary resin recipes are designed to enhance the bond's strength and durability, while still maintaining its self - sharpening and heat - reducing properties.

Hybrid - Bonded Diamond Grinding Wheels: The Best of Both Worlds

Unparalleled Performance

Hybrid - bonded diamond grinding wheels combine the advantages of different bond types, typically integrating the benefits of resin and metal bonds:

Enhanced Strength and Durability: By incorporating elements of metal bonds, hybrid - bonded wheels offer increased strength compared to resin - only wheels. This allows them to withstand higher grinding pressures and forces, making them suitable for more demanding machining tasks.

Precision and Control: The resin component in the hybrid bond retains the flexibility and self - sharpening characteristics, enabling precise material removal and maintaining a consistent cutting action. This balance between strength and flexibility results in excellent shape retention, ensuring that the grinding wheel can accurately reproduce complex geometries on CNC cutting tools.

Improved Heat Management: The hybrid bond structure facilitates better heat dissipation during the grinding process. This is crucial when working with materials that generate a significant amount of heat, as it helps prevent thermal damage to both the workpiece and the grinding wheel, extending their service life.

Optimal Use Cases

Complex Geometries and Profiling: Hybrid - bonded diamond wheels excel in grinding cutting tools with intricate shapes and profiles. Their ability to maintain shape accuracy while providing efficient material removal makes them the go - to choice for tool and die makers, aerospace manufacturers, and other industries that require high - precision shaping of cutting tools.

High - Volume Production: In mass - production environments, where consistency and productivity are key, hybrid - bonded wheels offer reliable performance over extended periods. Their durability reduces the frequency of wheel changes, minimizing downtime and increasing overall production efficiency.

Ruizuan's Innovation

At Ruizuan, our hybrid - bonded diamond grinding wheels are the result of extensive research and development. We have perfected the formulation and manufacturing process to achieve the optimal balance between the different bond components. Our wheels undergo rigorous quality control testing, including hardness testing, balance testing, and cutting performance evaluation, to ensure that they meet the highest standards of precision and reliability.

Selecting the appropriate grinding wheel for CNC cutting tools is a decision that should not be taken lightly. Whether you opt for the flexibility and precision of resin - bonded diamond wheels or the enhanced performance of hybrid - bonded diamond wheels, Zhengzhou Ruizuan Diamond Tools has the expertise and product range to meet your specific needs. Our commitment to quality, innovation, and customer satisfaction ensures that you can rely on our grinding wheels to deliver outstanding results in your CNC machining operations.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy