Mengetahui Perbezaan Sebenar Antara Berlian dan CBN

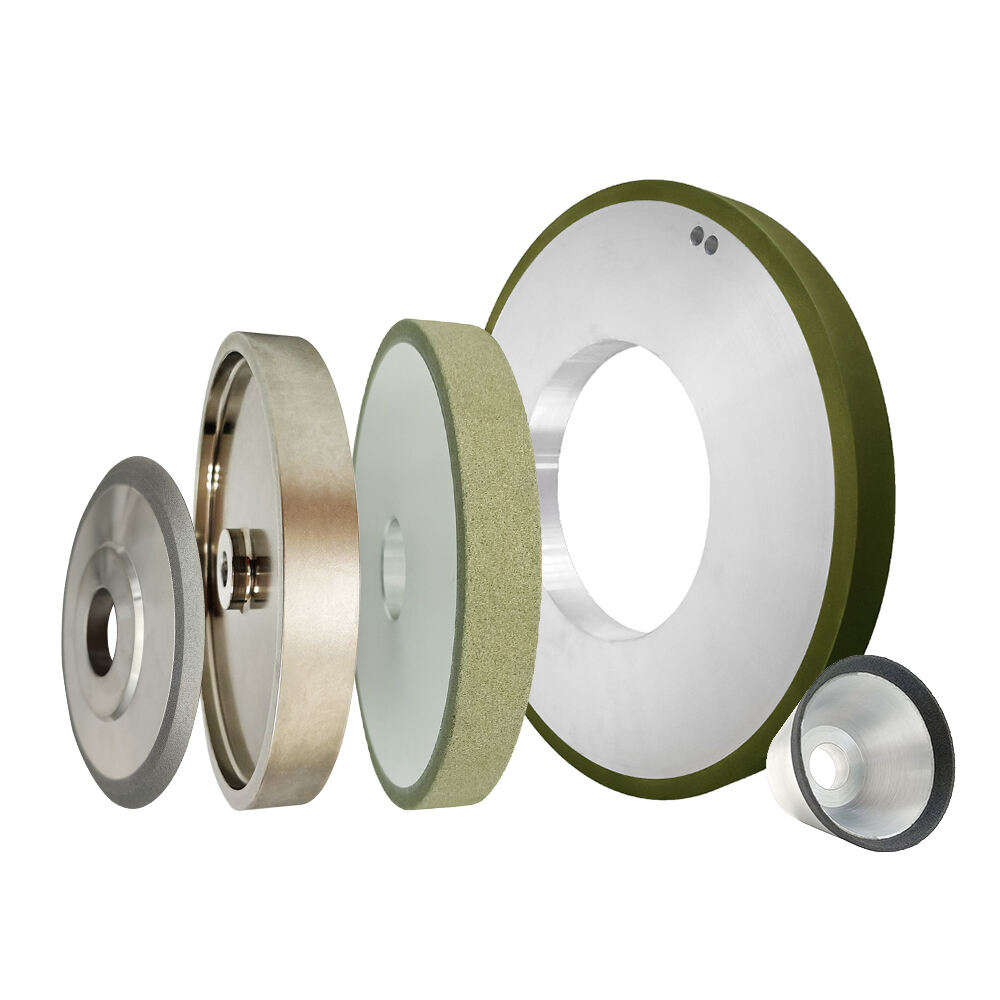

Untuk mengetahui roda yang mana akan tahan lebih lama; kita perlu memulakan dengan mengetahui pembinaan dan sifat kedua-dua jenis roda tersebut. Roda berlian mengandungi hablur berlian sintetik, iaitu bahan paling keras yang diketahui di bumi. Ini memberikan kadar penyingkiran bahan yang belum pernah dicapai sebelum ini pada bahan yang paling keras dan paling abrasif. Roda CBN : CBN merujuk kepada Cubic Boron Nitride, bahan kedua terkeras apabila berlian tidak tersedia. CBN juga agak kurang keras, tetapi ia mempunyai kestabilan haba yang cemerlang dan afiniti kimia yang bertentangan.

Jangka hayat roda yang panjang adalah hasil pemilihan roda yang paling sesuai untuk bahan kerja tertentu. Sangat cekap pada bahan bukan ferus. Roda gerinda berlian sesuai untuk proses pemesinan dan hampir tahan haus, tetapi hanya sesuai untuk roda gerinda dengan diameter tertentu. Ini termasuk seramik keras, bahan komposit maju, kaca, granit dan karbida tungsten. Apabila menggilap bahan-bahan sedemikian, roda berlian mengekalkan tepi potongnya lebih lama, jauh mengatasi sebarang abrasif konvensional. Bahan sedemikian akan cepat haus jika menggunakan roda CBN, menjadikan jangka hayat roda tersebut semakin pendek secara berkadar.

Sebaliknya, roda CBN direka untuk menggilap bahan ferus. Bahan-bahan tersebut mungkin termasuk alat yang telah dikeraskan dan keluli acuan, keluli kelajuan tinggi serta aloi berasaskan besi lain. Tindak balas kimia antara berlian (karbon) dan logam ferus di bawah suhu penggilapan yang tinggi menyebabkan fenomena yang dikenali sebagai "grafitisasi", di mana hujung berlian haus dengan cepat. CBN tidak aktif secara kimia terhadap besi, maka ia tidak bertindak balas dengan cara yang sama. Apabila anda menggilap keluli keras dan tahan lama, CBN akan kekal tajam dan mengekalkan bentuknya untuk jangka masa yang sangat panjang berbanding berlian yang akan habis digunakan dalam masa yang singkat.

Senario Aplikasi dan Ketahanan dalam Persekitaran Berat

Operasi penggilapan berat sangat kompleks dan menghasilkan haba serta tekanan yang tinggi. Jika perniagaan anda khusus dalam karbida, seramik atau batu, pilihan terbaik apabila mencari roda berlian berkualiti tinggi adalah dengan merujuk kepada Zhengzhou Ruizuan Diamond Tool Co., Ltd. Roda ini akan memotong secara sekata, yang bermakna kurang pertukaran roda, kurang masa hentian dan kos setiap bahagian yang kekal sama hari ini seperti juga sepanjang hayat roda tersebut. Jangka hayat roda meningkat disebabkan oleh fakta bahawa bahan pemotong berlian itu memotong bahan-bahan yang sesuai dari segi kimia dan fizikal dengannya.

Pemenang peluang untuk operasi pada keluli keras dan logam ferus lain adalah roda CBN. Dalam proses mencabar seperti penggilapan aci engkol, alat gear atau mata pisau, kestabilan haba CBN merupakan kelebihan yang ketara. Ia boleh digilap pada suhu tinggi tanpa kehilangan kekerasan serta rintangan terhadap serangan kimia. Hasilnya adalah roda yang mempunyai jangka hayat yang sangat panjang, tidak berubah bentuk (kerana habuk gilapan jatuh ke dalam cincin), dan mampu mencapai kemasan yang tinggi dalam tempoh masa yang lama. Rintangan haus yang luar biasa ini menghasilkan jangka hayat yang lebih panjang dan penjimatan kos yang signifikan dalam konteks aplikasi tertentu.

Pilihan Ekonomik yang Bertanggungjawab untuk Perniagaan Anda

Jadi, roda manakah yang lebih tahan lama? Seperti banyak soalan rumit dalam kitaran, soalan ini tidak boleh dijawab secara abstrak. Pemanjangan jangka hayat roda berlian dan roda CBN boleh dicapai dengan penggunaannya pada kumpulan bahan kerja yang optimum. Menggunakan bahan pemotong yang salah untuk bahan anda akan menyebabkan kehausan awal, prestasi yang buruk, dan operasi yang mahal.

Di Zhengzhou Ruizuan Diamond Tool Co., Ltd., kami ingin mengingatkan anda bahawa roda yang paling tahan lama adalah roda yang dikeluarkan dengan betul untuk aplikasinya. Berlian memberikan penyelesaian jangka hayat terbaik untuk bahan bukan ferus, keras dan abrasif. CBN sesuai untuk bahan ferus yang sejuk dan kuat, jika anda mahukan jangka hayat yang lebih panjang. Dengan panduan pakar teknikal kami, dan hanya dengan mengetahui bahan kerja utama anda, anda juga melabur dalam teknologi roda yang akan mempunyai jangka hayat yang panjang serta pulangan pelaburan yang baik untuk semua penggilapan berat anda.