Ottenere una finitura speculare perfetta e prolungare la vita delle mole superabrasive dipende da un componente cruciale: il montaggio corretto. La vibrazione, nemica della rettifica di precisione, danneggia la finitura superficiale e la durata della mola e può infine causare imperfezioni sul pezzo in lavorazione e usura a lungo termine del mandrino. Presso Zhengzhou Ruizuan, produttori di mole in diamante e CBN, abbiamo accumulato una vasta esperienza nella produzione di mole ad alta prestazione, quindi conosciamo esattamente il modo corretto di installarle sulla vostra macchina. Vi illustreremo tutti i passaggi necessari per garantire un montaggio corretto della mola, al fine di assicurare un funzionamento uniforme e privo di vibrazioni.

Scopri Perché il Montaggio È Così Importante

L'adattamento preciso tra la ruota e le flange della macchina è la base per un montaggio senza vibrazioni. Diamante e Disco CBN sono estremamente resistenti e non assorbono squilibri, pertanto non presentano vibrazioni né oscillazioni della ruota e possono normalmente essere utilizzati su una macchina senza puntale o altro supporto. Le tolleranze sul foro della ruota e le pressioni irregolari tra ruote e flange genereranno vibrazioni durante il taglio dell'albero. È consigliabile disporre di un sistema in cui l'insieme possa essere perfettamente centrato e fissato in modo uniforme. Prima ancora di toccare la macchina, verificare attentamente che tutte le flange della macchina siano prive di usura, corrosione o sporcizia. Una particella, anche un semplice granello di sabbia, posizionato sotto la flangia al momento del rimontaggio della ruota, può compromettere completamente tutto. Le flange devono essere pulite, piane e di diametro adeguato, generalmente non inferiore a un terzo di quello della ruota, per garantire un sostegno sufficiente.

Eseguire un controllo accurato prima dell'installazione

Il montaggio corretto inizia prima che la ruota venga posizionata sulla macchina. Sulle mole in metallo, ispezionare il disco e ascoltare il suono che emette; battere in diversi punti con uno strumento non metallico, come il manico in ghisa di un cacciavite o l'estremità di una chiave inglese. Controllare quindi i fori di montaggio della mola e gli alberi della macchina sui quali si adatta, alla ricerca di schegge o bave. Per evitare uno squilibrio iniziale, le superfici devono essere perfettamente piane. Pulire accuratamente il foro della mola e lo spessore della macchina con un panno privo di pelucchi. Qualsiasi residuo di polvere o pellicola potrebbe causare uno spostamento lieve ma percettibile. Se si posiziona la mola sull'albero e si deve spingere con molta forza, si avrà un problema! Non forzare col martello nel caso sia troppo stretta o bloccata, poiché si potrebbero danneggiare sia la mola che l'albero. Riesaminare e pulire le superfici.

Bilanciamento dell'insieme della ruota per le migliori prestazioni

Il corretto montaggio potrebbe non essere sufficiente per una perfetta centratura della mola: una mola nuova in diamante o CBN deve essere bilanciata per ottenere la massima fluidità. Si tratta di un processo essenziale per applicazioni ad alta precisione. La mola, insieme alle flange e alla boccola (se utilizzata), forma un gruppo rotante che deve essere bilanciato come un'unità singola. Per praticità, si consiglia l'uso di un banco di bilanciatura. La procedura consiste nell'installare l'intero gruppo sul banco di bilanciatura e individuare il punto pesante. La mola tenderà a ruotare sotto il proprio peso fino a quando il punto più pesante non si troverà nella posizione inferiore. È possibile correggere questo squilibrio regolando i pesi di bilanciamento. L'obiettivo è fare in modo che l'insieme rimanga fermo in qualsiasi posizione in cui viene lasciato. La bilanciatura della mola dopo il montaggio riduce drasticamente le vibrazioni, garantisce una migliore finitura del pezzo in lavorazione e prolunga la vita dell'abrasivo super resistente.

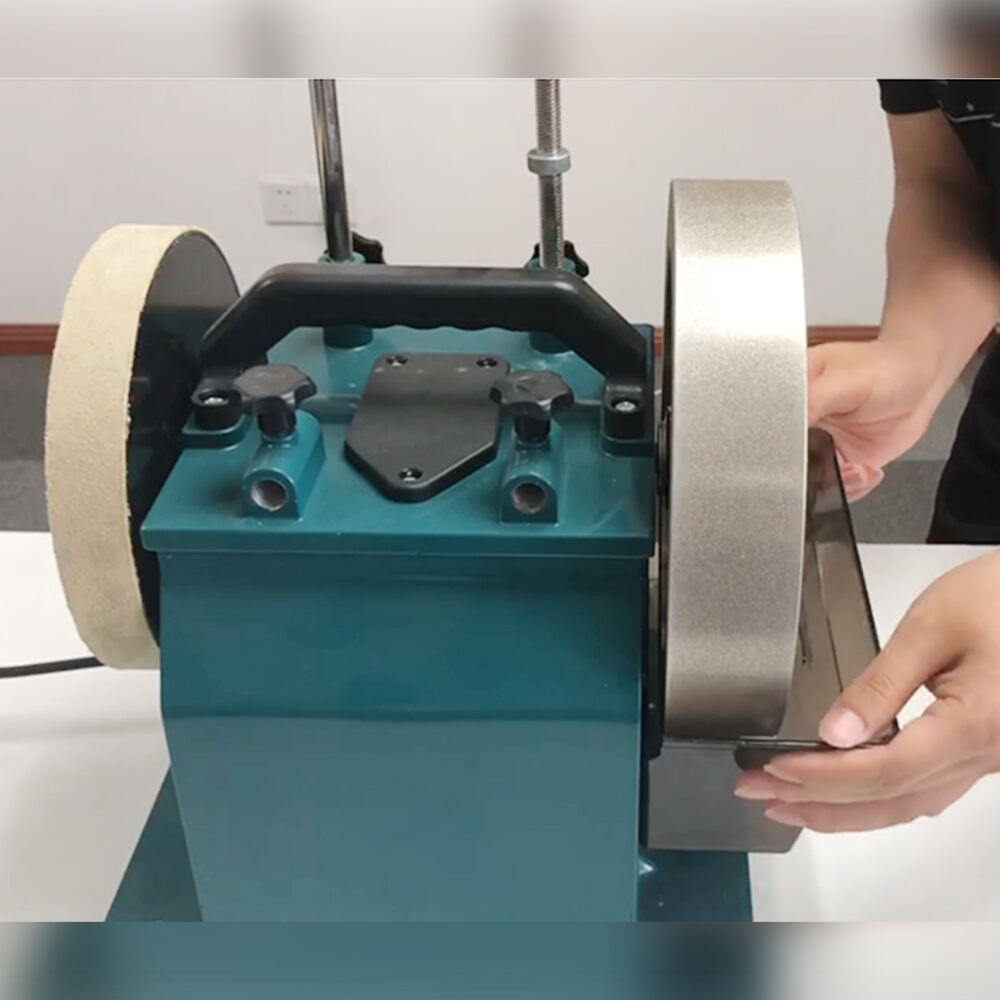

Procedura finale di serraggio e rodaggio

Quando la ruota è centrata, è il momento di tornare alla mola e montare la ruota. Stringere il dado di fissaggio con la chiave appropriata, avendo cura di non serrare eccessivamente per evitare di deformare le flange o crepare il mozzo della ruota. Si consiglia sempre di consultare i valori di coppia raccomandati dal produttore della macchina.