उचित चयन तीव्रक सामग्री प्रसंस्करण के लिए उपकरण बहुत महत्वपूर्ण है। हीरा और CBN (क्यूबिक बोरॉन नाइट्राइड) सबसे कुशल सुपर-एब्रेसिव सामग्री में से दो हैं। हालाँकि, वे एक दूसरे के स्थान पर उपयोग नहीं किए जा सकते। वे विशिष्ट सामग्री परिवारों के लिए अनुकूलित होते हैं। गलत उपकरण के उपयोग से सतह का खराब फिनिश, धीमी कटिंग गति और उपकरण का जल्दी घिसावट हो सकता है। यह लेख आपको उनके विभिन्न अनुप्रयोगों, प्रत्येक के मुख्य उद्देश्य, और विशेष रूप से ग्लास के लिए हीरा व्हील्स तथा उन मिश्र धातु सामग्री के लिए CBN व्हील्स के बारे में बताएगा जिन्हें पाया जा सकता है।

ग्लास ग्राइंडिंग के लिए हीरा व्हील्स सबसे उत्तम हैं

जब कांच को चिकना और आकार दिया जाता है, तो हीरे के अपघर्षक स्मूद केले के समान होते हैं! इसका कारण शामिल घटकों की अंतर्निहित विशेषताएं हैं। कांच एक कठोर लेकिन भंगुर पदार्थ है, जिसमें सिलिकॉन डाइऑक्साइड होता है। हीरा ज्ञात सबसे कठोर पदार्थ है और कुशलता से काटने में पूरी तरह से सक्षम है।

घूर्णन के दौरान धातु में निहित हीरे के कण कार्य-वस्तु के विरुद्ध रगड़ते हैं, जिससे नए कटिंग बिंदु प्रदान किए जाते हैं। वे कांच को इतने नियंत्रित तरीके से तोड़ते हैं कि एक साफ, छिलने से मुक्त कट बन जाता है। हीरे के कणों के कोणीय किनारे कांच को न्यूनतम उप-सतह क्षति के साथ काटने के लिए आदर्श होते हैं। इससे एक चिकनी परिष्करण और उच्च किनारा गुणवत्ता प्राप्त होती है -- जो दर्पण और खिड़कियां बनाने से लेकर जटिल कलात्मक कांच के काम और इलेक्ट्रॉनिक प्रदर्शन कवर तक हर चीज के लिए महत्वपूर्ण है।

हमारे हीरा ग्लास कटिंग व्हील्स, यह केवल एक और कारण है कि चेंग्ज़ौ रुइज़ुआन डायमंड टूल कंपनी लिमिटेड उद्योग में से एक सर्वश्रेष्ठ होने का दावा कर सकती है। हमारे हीरा ग्लास कटिंग व्हील्स को विशेष रूप से नौकरी के लिए एक बॉन्ड प्रणाली के साथ विकसित किया गया है और आपके उत्पाद पर केवल एक उत्कृष्ट फिनिश के अलावा भी बहुत कुछ प्रदान करता है। बॉन्डिंग केवल हीरों को पकड़े रखेगी ही नहीं, बल्कि यह नियंत्रित और समान घिसावट प्रदान कर सकती है जो इस बात को सुनिश्चित करने के लिए आवश्यक है कि ग्राइंडिंग के दौरान नए तेज हीरे के क्रिस्टल सतह पर लाए जाएं। यह स्व-तेज करने का व्यवहार TK व्हील्स को खुला और मुक्त कटिंग बनाए रखने की अनुमति देता है, जिसके परिणामस्वरूप लगातार प्रदर्शन और सेवा जीवन होता है जो किसी भी ग्लास कार्यशाला के लिए निवेश पर अच्छा रिटर्न प्रदान करता है।

मिश्र धातु ग्राइंडिंग: CBN व्हील्स सही उत्तर हैं

अब, जितना कठोर हीरा है, उसकी एक प्रमुख कमजोरी है: हीरा इस्पात के साथ रासायनिक रूप से प्रतिक्रिया करता है—एक लौह युक्त पदार्थ जो अधिकांश उपकरण शीट धातुओं का लगभग 75 से 80% बनाता है—जब ग्राइंडिंग के दौरान उच्च तापमान उत्पन्न होता है। इस प्रतिक्रिया के परिणामस्वरूप हीरे के अपघर्षक पर तेजी से क्षरण होता है, जिससे अधिकांश मिश्र धातु अनुप्रयोगों के लिए इसे अव्यावहारिक और अर्थहीन बना दिया जाता है। और यहीं पर CBN उत्कृष्ट प्रदर्शन करता है।

हीरे के बाद दूसरी सबसे कठोर सामग्री, क्यूबिक बोरॉन नाइट्राइड को अब एक विशिष्ट प्रक्रिया प्रौद्योगिकी का उपयोग करके लौह धातुओं पर लेमिनेट किया जा रहा है जिसके साथ बहुत सफलता मिल रही है। इसका व्यावहारिक अर्थ यह है कि जब कठोर, मशीन करने में कठिन सामग्री जैसे उपकरण इस्पात, स्टेनलेस स्टील और निकल-आधारित सुपरमिश्र धातुओं की ग्राइंडिंग की जाती है, तो हीरे के व्हील खरीदना वास्तव में अपने आप में लाभदायक साबित होता है क्योंकि 5,000 पिन्स के बाद भी आपके पास कटिंग एज बचे रहते हैं।

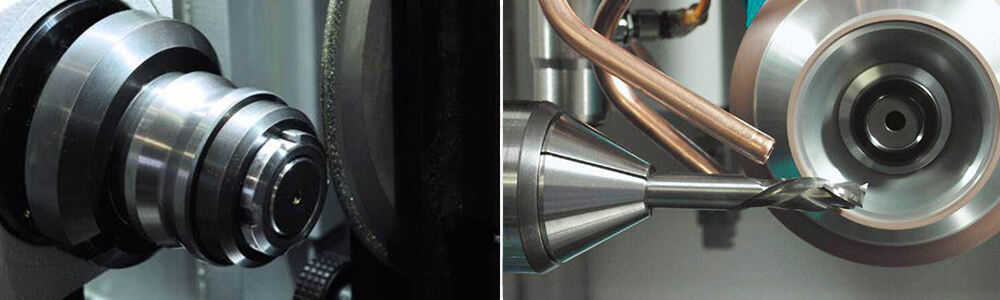

मिश्र धातु के खराद से, CBN के उपयोग में उत्पादकता और परिशुद्धता में काफी सुधार होता है। वे अन्य सामग्री की तुलना में तेज कटिंग गति पर चलते हैं और कम ऊष्मा उत्पन्न करते हैं, जिससे कार्य-वस्तु की सतह पर ऊष्मीय क्षति या जलने और सूक्ष्म दरारों को रोका जा सके। बाद वाला क्रांतिक मिश्र धातु घटकों की अखंडता और आयु के लिए आवश्यक है। वे तंग सहनशीलता के साथ लगातार लंबे समय तक खरादने पर भी अपने आकार को बहुत अच्छी तरह से बनाए रखते हैं। जब आप उच्च-शक्ति वाले मिश्र धातुओं को मशीन कर रहे हों, तो झेंगझोउ रुइज़ुआन डायमंड टूल कंपनी, लिमिटेड जैसे विशेषज्ञ से CBN प्रौद्योगिकी में निवेश करने का अर्थ है कम डाउनटाइम ग्राइंडिंग व्हील और बेहतर फिनिश गुणवत्ता के साथ प्रति भाग ग्राइंडिंग लागत में कमी।

अपने अनुप्रयोग के लिए सर्वोत्तम विकल्प का चयन करना

सीबीएन और हीरा के बीच निर्णय मूल रूप से आपके कार्यपृष्ठ के सामग्री पर निर्भर करता है। एक मूल नियम के रूप में, ध्यान रखें कि: संपर्क व्हील के सबसे अच्छे प्रकार गैर-धातु और अतिरिक्त कठोर सामग्री जैसे कांच, सिरेमिक या कार्बाइड पर उपयोग के लिए बनाए गए हैं। दूसरी ओर, सीबीएन व्हील केवल धात्विक सामग्री के लिए डिज़ाइन किए गए हैं।