Cylinder grinding means the process of peripheral grinding of a rotary work piece which is held between two centers or is gripped by a chuck. RUIZUAN’s high cutting ratio cylindrical grinding wheels are suitable for grinding the peripheral surface of straight cylinder or taper cylinder work piece which with concentric requirement、mold、spindle and traffic equipment. And provide the best solution for customers’ requirement on grinding process.

MOQ: 5pcs

Cylindrical grinding wheels is used on Cylindrical grinding machines. RZ brings Cylindrical Grinding Wheels with different abrasives. Aluminum Oxide Grinding Wheels, Silicon Carbide Grinding Wheels, Diamond Grinding Wheels and CBN Grinding Wheels are all available.

REZZ will provide you with system solutions for industries such as Gear grinding, Auto components grinding, Roll Cylinders grinding, Journals grinding, crankshafts grinding, Long hydraulic cylinders grinding, chilled cast iron rolls grinding, rubber rolls grinding, copper roll grinding, and granite rolls grinding.

Features:

* Enables precise cylindrical surface finishing for workpieces.

* High grinding efficiency with continuous surface-workpiece contact.

* Guarantees good dimensional accuracy and tight tolerances.

* Creates fine surface finishes (low Ra).

* Versatile for grinding diverse materials (Customized abrasives)

|

|

Grinding Methods:

| Abrasive | Diamond, CBN, Ordinary Abrasive |

| Bonding | Vitrified, Resin |

| Model | 1A1, 3A1, 14A1, etc |

| Popular Sizes | 50-900mm |

| MOQ | 5 Pieces |

|

Application:

Grinding Workpiece: Gears, Auto components, Gears, Roll Cylinders, Tool holders, Journals, crankshafts, Long hydraulic cylinders, chilled cast iron rolls, rubber rolls, copper roll, and granite rolls.

Applicable Tool Material: PCD, tungsten carbide, ceramics, magnetic material, tungsten steel, high-alloyed steels ,HSS, stainless steel bar.

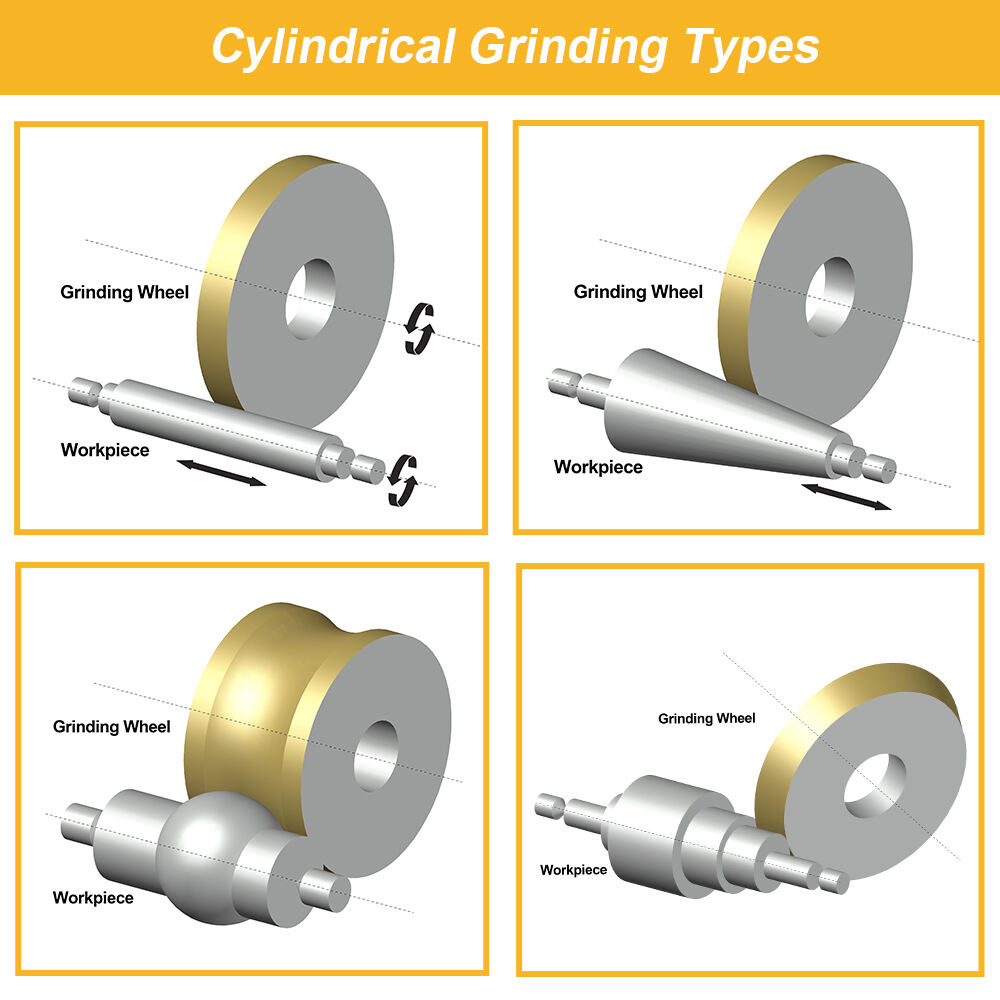

Grinding Method: External cylindrical grinding, internal cylindrical grinding, thread grinding, Profile cylindrical grinding, Non-round grinding / contour grinding.

CNC Applicable Grinding Machine: Okuma, Toyoda, Studer, Junker, Kellenberger, SHARP, Landis, Bryant, Supertec, Cincinnati, Heald, Okamoto

Universal Applicable Grinding Machine: Cincinnati, Supertec, Landis, Brown & Sharpe, Toyoda, Okuma, Jones & Shipman, Shigiya, Studer, TOS Hostivar, Doosan, Okamoto, and Fermat.

Specifications:

| Dimensions | |

| Wheel Shape | 1A1, 3A1, 14A1, etc |

| Size | 50-900mm |

| Grinding Wheel Material | Silicon carbide, Corundum, Aluminum oxide, Diamond, CBN |

| Grinding Workpiece Material | 1. Diamond Cylindrical Grinding Wheels mainly used for grinding PCD, tungsten carbide, ceramics, magnetic material, stainless steel bar 2. CBN wheels are mainly used for grinding steel materials, while diamond wheels are used for the cylindrical grinding of tungsten steel, ceramics, and other materials. 3. Corundum grinding wheels are used for hardened or non-hardened steel rolls. Silicon carbide grinding wheels are used for chilled cast iron rolls, rubber rolls, copper roll, and granite rolls. For steel rolls with different materials, the corundum grinding wheel should be matched to obtain high grinding precision and surface quality. |

| Any nonstandard size and grits can customized.(tell me size or drawing is enough) | |

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy