Grinding is a process that is expensive and causes work piece burning every time it is used in precision manufacturing. It undermines surface integrity, causes metallurgical damages and rejects. To users of superabrasive wheels, it is important to know that the wheel is one major variable that can be used to prevent this issue. We are Zhengzhou Ruizuan Diamond Tool Co., Ltd. and we are the manufacturers of Diamond and CBN grinding wheels, which are not only engineered to work efficiently, but also in terms of safety in the process and quality of the surface. The most effective method of eliminating burning is often the proper adjustment of the parameters of the wheel.

The Choice of the Abrasive Type is a Prerequisite

The initial decision that needs to be made critically is the one between Diamond and CBN abrasives. CBN (Cubic Boron Nitride) is very suitable to the grinding of ferrous material, hard and brittle steels in particular. It is also chemically inert to iron and has high thermal stability, which ultimately leads to reduced heat generation and to a lesser reaction with the workpiece material, a direct effect of which is the reduction of the risk of thermal damage. Diamond is harder but is normally used to handle non-ferrous metals, ceramics and carbide. When the wrong type of abrasive is used to force the process to work against the material properties, excessive heat is bound to result. This is the primary decision that we take our clients through in order to create a cool-grinding basis.

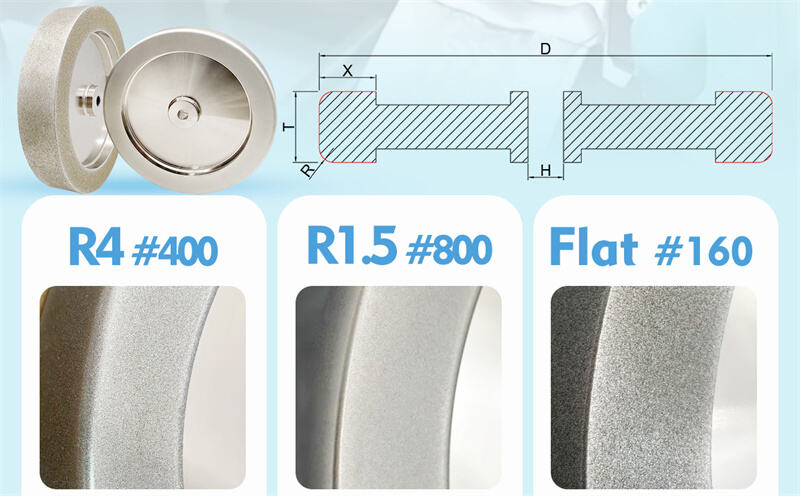

Optimizing Wheel Grade and Grain Size

Two of the most powerful parameters that you can modify include grain size (grit) and wheel grade (hardness). Larger chips and more open spaces between grains to allow coolant to penetrate and swarf to be removed are obtained by increasing the grain size. This arrangement eliminates the amount of heat that accumulates at the grinding zone. On the other hand, a too hard or a high grade wheel will not shed off dull grains easily. A dull wheel produces friction and heat. To avoid cutting a harder grade of steel, a somewhat softer grade can be used where the wheel will sharpen itself creating new, clean cutting edges with less power and heat production. Our technical department will help in suggesting the best grit and grade mix to use in your material and application.

The Wheel Structure and Bond are Critically Important

The structure of the abrasive grains, concentration and pattern of the grains, and bond material that contains the grains is crucial to the heat management. There is a free structure wheel that offers extensive porosity. Such pores provide a path to coolant that flows to the cutting zone and deposits to eject the grinding chips ensuring that the chip does not re-cut the work piece and heat up. The bond material, be it resin, vitrified or metal should also be matched to the application. An example may be used to illustrate that some of the vitrified bonds provide a great porosity and dressing attributes to produce a uniform, free-cutting activity. Our wheels are designed to control and engineer their structure to have a consistent performance and thermal management.

Implementing Effective Dressing and Using Ample Coolant

A perfectly specified wheel may burn when not maintained properly. Proper and frequent dressing cannot be compromised. It cuts the wheel, and gives it back its shape, and cleans up the pores. An ill-dressed wheel is dull and glazed and it becomes a trap of heat on the piece of work. Moreover, there is no parameter adjustment that would be effective without an efficient plan of coolant. Apply high-quality coolant, use adequate flow and pressure, and apply it at the contact point of the wheel-workpiece, and make sure that it is filtered and clean. A properly-dressed, open-structure wheel plus a large quantity of coolant is a strong protection against thermal damages.

Collaboration to find a Comprehensive Solution

There is seldom one change in solving workpiece burning. It consists of a synergistic change in wheel specifications and process parameters. In Zhengzhou Ruizuan Diamond Tool Co., Ltd., we do not only offer quality Diamond and CBN wheels. We provide application support to assist in analysing your grinding process. With your machine tool, material and result in mind we can work out a wheel that will run at lower temperature and longer life so that a burning problem can be a high productivity and unparalleled part quality opportunity. Call us to have the cool-cutting solution to your most difficult grinding problems.