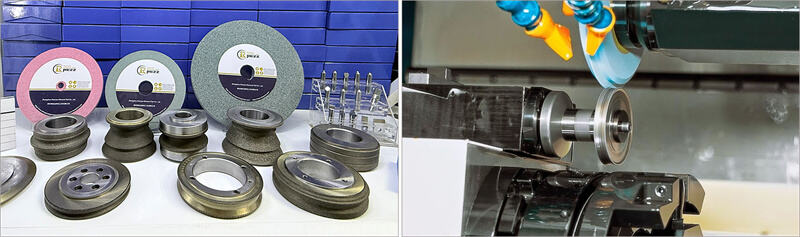

To get quality and efficiency, it is better to maintain your grinding activities at the maximum level of performance. The dressing of the wheel is one of the most significant maintenance jobs making the wheel be trued and possessing its cutting capacity again. Such a process is not comparable to the standard wheels in case of super-abrasive tools such as diamond and CBN grinding wheels. We are involved with the most performing tools in Zhengzhou Ruizuan Diamond Tool Co., Ltd., and the majority of the people are interested in finding out the best frequency of dressing. It is not a simple figure since it is subject to different variables. This manual will make you understand when and why to dress your diamond and CBN wheels.

Finding the heart of Why Dressing Super-Abrasive Wheels.

Sharpening the abrasive grains in a dress of a diamond or CBN wheel is not a question. These hard materials are super hardened such that they stay sharp during very long periods of time. Instead, there are two significant purposes of dressing. The latter is to stabilize the wheel, which has acquired some slight run-out or geometrical errors. This ensures that your workpiece is finished smoothly because the wheel is cool in shape as it is perfectly concentric. The second and more common one is the removal of a stratum of swarf or bond impregnation. During the grinding, the metallic components may be clogged in the wheel bond pores, this glazes the surface. This results in clogging of this wheel, decreases the cutting performance of this wheel, increases forces of grinding and even leads to thermal effects on the work piece. The dressing removes the obstructions, and new sharp grains of abrasive are disclosed, and the free-cutting effect is restored.

The notable variables that determine the frequency of dressing.

There is no standard procedure on dressing diamond and CBN wheels. The right moment is everything in the application which you must make. These are the primary factors which you need to consider. The major aspect is what its ground is made of. More challenging or stubborn materials or those that result in gummy swarf can load the wheel faster and this can necessitate more frequent dressing. It is also dependent on the workpiece finish that is required. Some finer surface finish will require a more open and free-cutting wheel, which will require more frequent dressing to maintain. Feed rate and depth of cut are also important parameters of grinding. Independent loading Aggressive grinding might hasten the loading of the wheel. Finally is the specific bond fashioning of your wheel, which has been built by such manufacturers as Zhengzhou Ruizuan Diamond Tool Co., Ltd., and is being served by all these causes. A weaker bond will tend to refine itself and require less dressing, and also a hard bond will require more traditional dressing to prevent loading.

General Dressing Instructions and Hints.

You cannot have a definite schedule, but you can come up with a reliable schedule on a case-by-case basis. First of all, there are noticeable behavioral signs of necessary dressing apparent physically and functionally. Hear the grind. An acoustic modification, especially, an upward pitch of a squeal or an augmentation of the quantity of noises, is often an alert of a loaded wheel. When visible burnt or discoloration marks are observed on the workpiece this is evidence of excess heat produced by an overloaded or choked wheel. Feel the process, if possible. Lack of stiffening of grinding resistance or vibration is a good sign to a high degree. The visual examination of the surface of the wheel can also be observed; the surface is usually shining, glazed that is an indication of the material loading. To avoid most of the operation failures, most of the successful operations dress their wheels at the beginning of each shift or a work piece batch change.

Dressing: Best Practices in Dressing Diamond and CBN Wheels.

Doing the correct dressing technique does not become any less important than the frequency. It is directed at stripping away just enough of the bond matrix to expose sharp new grains without being too destructive of them. Always use a special dressing stick, e.g. silicon carbide or aluminum oxide stick, which is not so hard as the super-abrasive wheel. Dressing must be done with slow steady traverse, light and continuous pressure. Needless to say, the dresses cannot be aggressive, as that will cause damage to the diamond or CBN layer, as well as the profile of the wheel too early. The debris may also be cleaned by dressing up with a great deal of coolant to ensure that the temperatures are kept down. You will have ensured that you will be having the maximum life of your investment and the maximum performance of that investment by adhering to the dressing tips provided by your wheel manufacturer.

Lastly, it is very crucial that one dresses their diamond and CBN grinding wheels in a process in order to have a consistent and quality results. With the awareness of that purpose, being aware of the indications and applying the appropriate procedures, you will be in a position to ensure that you get the most out of your dressing schedule, along with the life of your wheel, in the best possible way. We do not only produce the best super-abrasive products in Zhengzhou Ruizuan Diamond Tool Co., ltd, but we also have the intention of sharing the technical information about the products with you in order to know how to use them.