Diamond Wheels vs. CBN Grinding Wheels A Comparison

As far as precision grinding is concerned, the choice of the appropriate abrasive wheel is the key to reaching the necessary finish, efficiency, and cost-effectiveness. Diamond and Cubic Boron Nitride (CBN) grinding wheels are among the most advanced and highly effective options that are available. Although they may appear as one to the uneducated they are intended to perform diametrically opposite roles. Their peculiarities are the keys to their maximum possibilities in your work.

Learning the Core Materials

The major distinction between these two super-abrasive wheels is based on their basic composition.

Industrial diamonds are used as the abrasive grain in diamond grinding wheels. These wheels slice as they do because diamond is the hardest substance known. Such high hardness makes diamond wheels extremely appropriate in grinding non-ferrous materials. This is because they can retain a sharp edge, which they use to cut away material on these challenging surfaces with precision and speed.

CBN grinding wheels, however, consist of Cubic Boron Nitride which ranks second to diamond in hardness. But its major strength is not only its hardness, but its great thermal and chemical stability. CBN is not sensitive to iron and its alloys like diamond. It follows that it is not chemically reactive with steel at the elevated temperatures produced during grinding, which is an essential consideration that determines its primary use.

Key Applications and Use Cases

The various chemical characteristics of these abrasives are what determine the materials they are suited to work with directly.

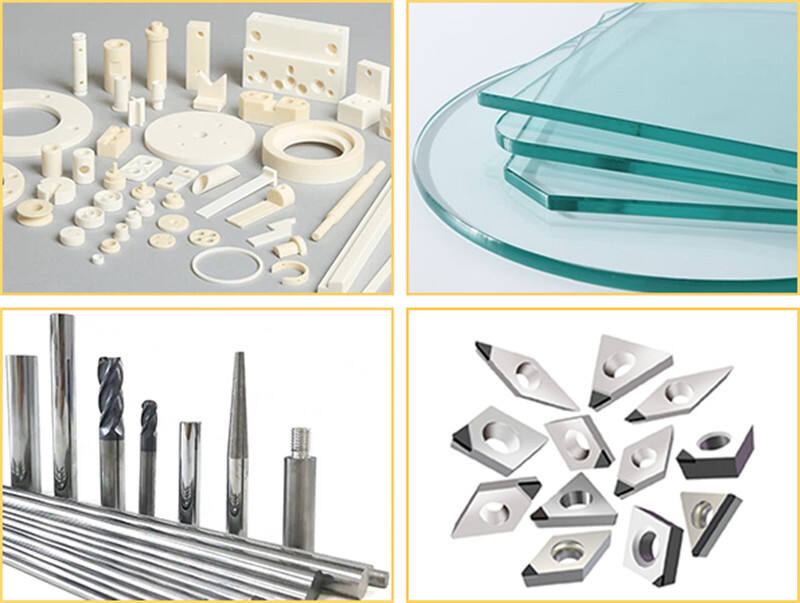

Diamond wheels have emerged as the undisputed king when it comes to processing non-metallic and non-ferrous materials. The reason being that they are far more harder and capable of cutting carbide, glass, ceramics, and stone and some types of composite very easily. A diamond wheel is the only tool which can be utilised with a tungsten carbide tool or with engineering ceramics to economically and effectively grind. It remains in form and cuts much longer on these abrasive materials than the normal abrasives.

CBN wheels, however, are designed to take away hard ferrous metals. They are the ultimate solution to hard steels and iron alloys because they are chemically stable. Its application is grinding tool steels, die steels, case-hardened steels, and also superalloys like Inconel. CBM is a material that performs well at maintaining its cutting profile and will not break up when exposed to the high stresses and temperatures experienced during the grinding of these materials, leading to superior workpiece integrity and reduced thermal loss.

The Right Tool to Use

Whether to use a diamond or a CBN wheel is not about which one is better than the other but about the one that suits your material.

The rule of thumb is this: a non-ferrous material is to be cut on a diamond wheel, and a ferrous material is to be cut on a CBN wheel. Cutting a diamond wheel on steel would be slow and economically impossible, because the carbon of the diamond would readily dissolve in iron at high temperatures, so the wheel would be worn down at an impossible rate. The thermal stability of CBN permits it to stay much longer on steel.

Apart from material compatibility, the advantages of every wheel are unique. Diamond offers the hardest among the non metallic materials. CBN has outstanding thermal resistance and this means less heat in the cut, a smoother surface finish and longer life of the wheel in hard steels. This minimization of heat production is essential in maintaining the metallurgical characteristics of the workpiece and avoiding burns.

Conclusion

Diamond and CBN grinding wheels are the best of the abrasives, and these are specialty tools. Ceramics and carbides are ruled by diamond, which is the hardest, and CBN, which is the most stable and the best performer on hard steels. Manufacturers can reach unprecedented standards of productivity, precision and part quality by closely aligning the wheel with the material, and make the most magical use possible of their grinding operations.