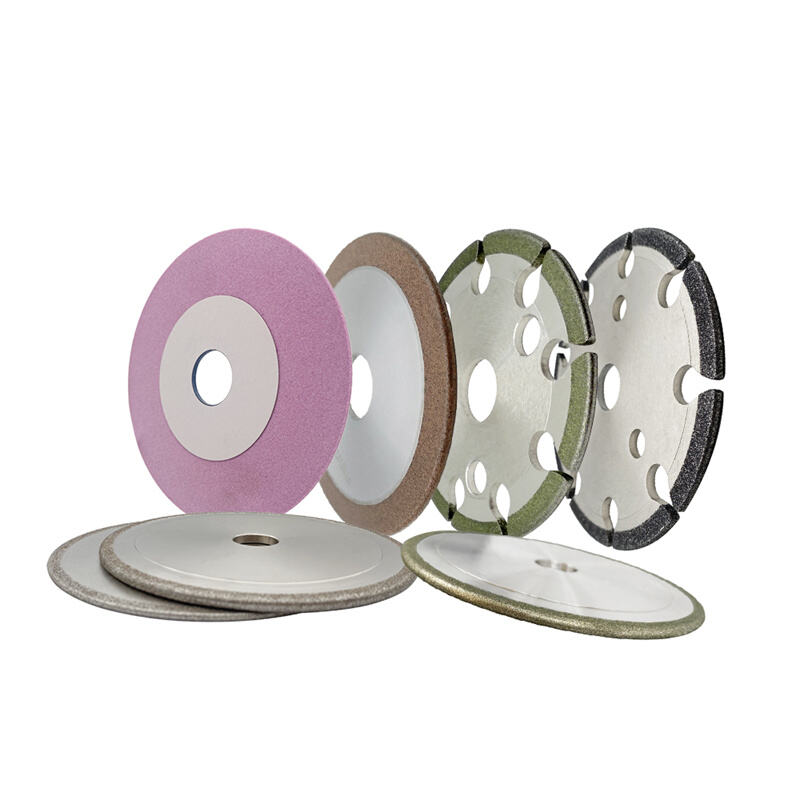

Where the finish of the surface in precision grinding is to be taken to the highest perfection, the question of the abrasive wheel becomes critical. This high-performance arena is dominated by two superabrasive materials diamond and cubic boron nitride (CBN). On the manufacturers and craftsmen in need of a mirror-like finish, the argument is usually whether which wheel can offer the best finish. However, the solution does not lie in a mere statement but in an informed choice depending on the material you are working on. We are the manufacturers of both diamond and CBN wheels at Zhengzhou Ruizuan Diamond Tool Co., Ltd., and we have come to help people unravel this very important decision.

Diamond and CBN Wheels - Knowledge of the Fundamental Nature.

Diamond wheels are the clear winner when it comes to non ferrous material grinding. They cut through carbide, glass, ceramics and composites with a lot of precision since they are extremely hard. This step saves unnecessary friction and heat which are the main culprits to poor surface finish. A diamond wheel, when used on the right material, can easily create an extraordinarily clean, sharp and smooth surface by cutting the material cleanly in a microscopic scale with no sub-surface harm or burn.

CBN wheels on the other hand are designed specifically with hard ferrous. Although diamond is more resilient, it reacts chemically with iron based metals such as steel and iron alloys at high temperatures that results into rapid wear of wheels. CBN is superior in the field as it is thermally and chemically more stable with such materials. It keeps its cutting edge far longer, and it leaves fine chips behind rather than heat destruction. This is the secret of its capacity to realize an extremely smooth finish to hardened steels and superalloy.

The Vital Interconnection between Material Compatibility and Surface Finish.

This quest to achieve a smoother finish is inherently connected with the choice of the wheel that will be chemically and mechanically compatible with your work piece. A tool steel, of either type, would be ruined in seconds using a diamond wheel, and leave the part with a scratched and rough finish. The material would be glazed and burnt by the wheel. Making a cut with a tungsten carbide would, on the other hand, be extremely ineffective, and would not result in any appreciable cut, much less a fine finish, when using a CBN wheel.

In the case of such materials as tungsten carbide, high-tech ceramics, or even green carbides, a high-quality diamond wheel of Zhengzhou Ruizuan is the only way to achieve an excellent surface finish. It has a sharp, consistent cutting surface in our wheels which reduces the grinding forces and avoids the creation of micro-fractures, which results in a polished, clean finish. The capacity of the wheel to remain cool and sharp simply goes into a high finer workpiece.

The CBN wheel is the unquestionable choice where your project entails tough ferrous metals such as high-speed steel hardened, die steel, or nickel-based alloys. It is chemically inert thus avoiding excessive heat and wear common with other abrasives. This permits a continuous fine-grain cutting action which refines the surface to a very low roughness average (Ra). The end product is a perfect, frequently glossy finish, which can be held to the strictest of demands.

Making the Right Choice to Your Application.

Then in the end your material provides the answer as to which wheel produces the more finished surface. No one is a universal winner, and the best tool of the job is the best. The real trick in getting such a perfect surface is not to seek a single best wheel, but to collaborate with an informed supplier who has the perfect wheel to your particular needs.

Zhengzhou Ruizuan Diamond Tool Co., Ltd. offers a big variety of diamond and CBN grinding wheels. We know our stuff so you will be armed with the right superabrasive solution to make the most out of it, increase the life of the wheels and most importantly the perfect finish on the work that you are known by. Call us and present your application today, and allow our experts to show you the right wheel to ride on to incomparable smoothness.