Precision grinding is a basic manufacturing and metalworking technique, where obtaining the specified surface finish and dimensional accuracy is important. One of the most important factors affecting the result is choice of proper abrasive grit size. The grit size defines the amount of material removed and the finished surface texture. The right grit selection can help make a big difference in the efficiency and quality of your work.

Determining Abrasive Grit Sizes

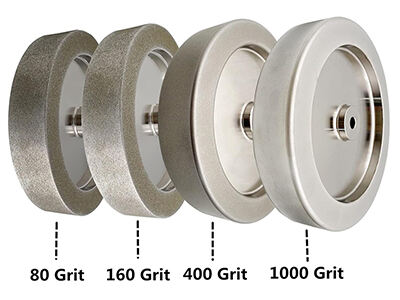

Grit size is the size of the individual coarse abrasive grains on a grinding wheel or other abrasive tool. It's typically represented by a number. A lower number is a coarser grit with larger abrasive grains, which remove material more aggressively. Conversely, a larger number represents a more fine, smaller-grit grit that's better suited for smoothing and polishing surfaces to a high finish. This numbering system is standardized for ease of selection of the abrasive needed for a particular application.

The abrasive tool consists of the matrix of these individual grains bonded together by the matrix bond. While grinding, the grains act as infinitesimal cutting tools. The coarse grains remove metal deeper and more rapidly, and the finer grains remove metal closer to the surface, polishing it. Moreover, the spacing between grains influences the regulation of chip clearance and heat production in grinding.

Key Selection Criteria for Grind Size

There are some key selection criteria involved when selecting a grit size for a precision grinding operation. The major aim is to provide an equilibrium between material removal rate and surface finish.

The material that is being worked is an important factor. Harder materials will often require a more fine grit for a clean cut without heating or damaging subsurface material. Softer materials may permit a coarser grit as a way of removing stock quickly. How much material there is to remove is just as important. If you're removing heavy stock, the most efficient starting point is a coarse grit. This is followed by gradually reducing grits in order to achieve the desired final surface finish and tolerances.

The final surface finish requirement is perhaps the most direct determinant in grit choice. A coarse finish on a part to be painted may require only a 60- to 120-grit tool. A part that needs a functional surface may require finishing to a 180- to 400-grit. For very precise work and mirror-like finishes, very fine grits of 800 and upwards are required.

Hands-On and developmental application

A common approach with precision grinding is to run a series of grits. A very fine grit is not normally used to remove large amounts of material; this is inefficient and can quickly clog the abrasive tool. Instead, the process starts with a coarse grit to cut the bulk of the material off rapidly and lay the basic shape.

Once most of the stock is removed, the surface is finished using an intermediate grit to smooth out the surface and eliminate the scratch marks of the coarse grit and bring the part towards its final dimension. Finally, a fine or very fine grit is used to attain the exact tolerance, and the specified surface finish. This sequential approach is sure to be efficient, preserves the life of finer abrasives, and gives a superb finish.

Prevention of Common Errors

A usual error is beginning with a fine grit for the initial stages of work, causing lack of progress and later thermal damage by means of friction. Conversely, employing a grit finer than required for the final finish will leave deep scratches in the surface difficult to remove afterwards. A second error is failure to employ the grits in sequence. Going from a very coarse grit to a very fine grit will usually be slower, the fine grit will struggle to remove the deep scratches, and never reach the desired polish. Understanding what each grit size is for and progressing through them in a coherent sequence is the secret to successful precision grinding.

Finally, selection of the right grit size is not a matter of one size fits all. Selection is done deliberately and based upon the material, removal of material and final surface finish to be achieved.