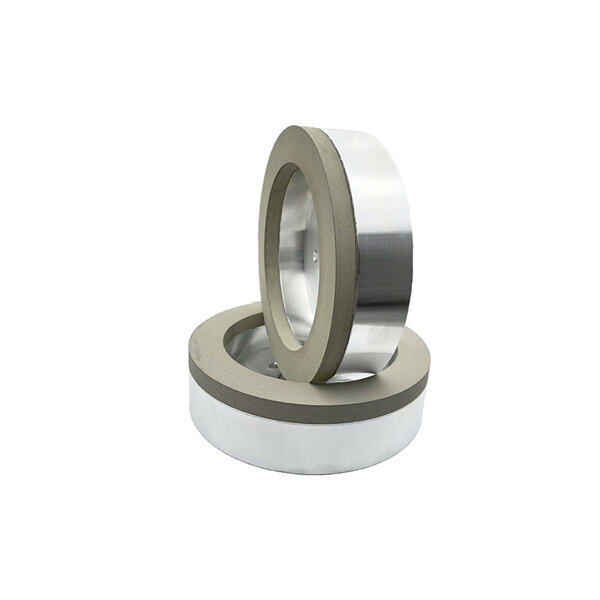

To use a diamond grinding wheel cup, when you want to make it smooth and shiny. It's an extremely powerful tool because it runs at very high speed. As it does spin, it cuts rough slopes from the surface and polishes it more fluidly. Manufacturing grinding wheels could contain various substances including diamond, ceramic, and aluminum oxide. But for most of you, you can say that steel grinding wheels are some of the best choices when it comes to better grinding metal surfaces right.

A grinder disc diamond consists of many small fragments of metal that are bonded using a special adhesive called bond. The bond is especially critical because it holds all the many pieces of steel in their place when the wheel spins at high speed. If this bond is weak, the wheel may shatter — with potentially catastrophic results. So, that bond has to be proper if you have to roll on the wheel without any hassle.

Selecting a steel grinding wheel is an excellent choice when it comes to grinding metal. Alloy wheel made of alloy, which is a very durable and sturdy material capable to bear High pressure without any breakage. It removes metal also very quickly. This indicates it helps you get your task done swiftly without resorting to needless effort and so, you may shift your focus towards other functional activities. Steel Grinding Wheel: This can save you lots of time and energy.

You can use a steel grinding wheel, and it will help you get very smooth metal surfaces. Smooth finish is very important because you want your metal to look nice and professional. It's something that can be difficult to do with other tools. The metal gets ground down uniformly by the steel grinding wheel, which means that no rough parts will be left behind and there will be no bumps. A smooth surface is very essential if you intend to bring your metal object to a certain shine and desirability.

You are going to need tools that can keep up with your project, If you're working on larger projects. Steel grinding wheels are the durable ones that can handle a lot of wear and tear. This suggests that it is resilient, and you can not stress over its malfunction any time quickly. Besides, it can also use a steel grinding wheel on some other materia(l)s such as steel, aluminum, brass, etc. This makes it well-suited for a wide variety of projects.

Every client has their own specific requirements. We provide bespoke and customized grinding wheels that are specifically designed for each requirements. We work closely with our customers to develop custom products that enhance their efficiency and effectiveness, while ensuring satisfaction of the customer.

We're committed to delivering high-end quality products and excellent service. Our stringent quality control procedures ensure that every grinding wheel meets the highest industry standards, providing our customers with trust and assurance. Our customer service staff is ready to help and provide a seamless ordering-to-delivery experience.

Our research and development team is always exploring new materials and processes to ensure that we remain at the forefront of the abrasives market. We put a lot of emphasis on the performance and sustainability of our products as well as offering high-quality grinding solutions to keep up with the needs of our customers. We are here to help you achieve accuracy, quality, and innovativeness in all grinding applications.

REZZ is a grinding wheel manufacturer since 2014 and we have plenty of knowledge in supplying solutions for grinding wheels. We provide a broad range of custom Diamond CBN grinding wheel services that aid our industrial and manufacturing customers design better products as well as reduce their operating costs.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy