For centuries, humans have relied on the diamond grinding wheel cup as a primitive tool for sharpening bladed implements and tools. It is something that has a long history and has been influenced for many tasks. In this read, we will find out how the grinding stone evolved with time, what is the right way of using it, its types available in the market today, and how to maintain your grinding stone along with some crazy and innovative uses till date.

The engines of blade sharpening are the toughest tasks but this can be made easy by using a grinding stone. The first step involves soaking the grinding stone in water for at least a few minutes. It is advisable because the stone will work better when you sharpen your blades. After soaking, put the blade you wish to sharpen onto the flat side of grinding stone. Next carefully place the blade against the stone and glide it back and forth. A vital element to this method is maintaining a proper angle on the blade throughout the process. The sharper you saw in, the sharper you will see the bladeýr action. After sharpening, be sure to rinse the blade with water and then dry it thoroughly with a towel. Note: Do not overlook safety while working with a grinding stone!

This historical sport is thousands of years old — The dressing tool for grinding wheel. Initially, it was composed of natural stones, and humans used it to bring their primitive implements to a point. Since the old grinding stone was changed years. Over time, grinding stones have been benefited by many technological advancements in terms of the materials used to construct them. They used to be made from simple pieces of rock, but are now more frequently constructed out of stronger materials such as carbide or diamond grains that perform far better than the old rocks. Since we now use it to get blades sharpened, grind metal and polish surface to rust as well.

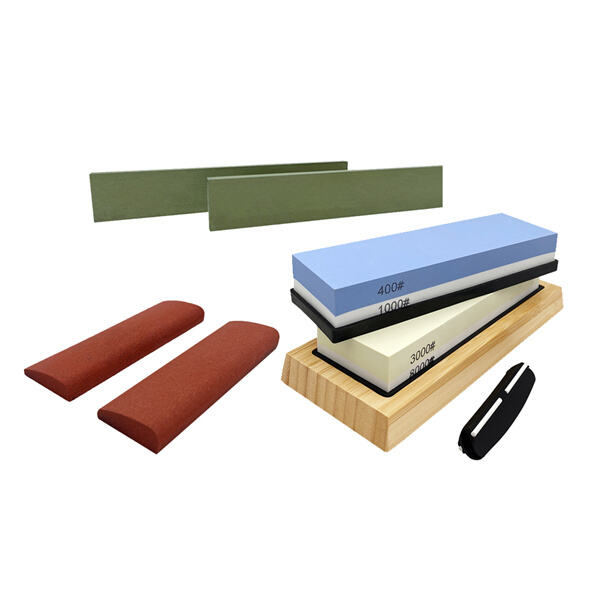

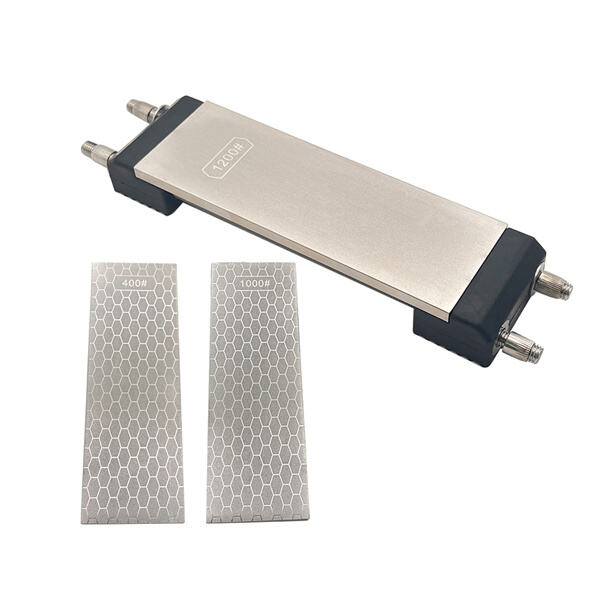

However, there are different varieties of grinding stones which vary in its uses. The silicon carbide grinding stone is one of the most common types of these stones. Perfect for sharpening any blade, from knives to scissors. And the last of them is the aluminum oxide grinding stone, as it works best for making tools sharper where you need to be extremely accurate and precise. Last is the diamond grinding stone, a perfect tool for hard metal grinding and suitable also for sharpen ceramic blade. Each of these stones has its intended purposes, so you should pick the one you need for your work.

If you want your grinding stone to last for a long time and continue functioning properly, then you need to take care of it. Wash it well with water after every use and dry it properly. Just ensure you avoid leaving it wet as rust would render it useless. You should also keep your grinding stone in a cool, dry place so that it does not become moist. A nice wet stone will be more than capable of serving you through countless sharpening jobs and the proper care with it, everyday usage too is going to serve you longer than one tends to believe. Always inspect your grinding stone and replace it when necessary (when worn/damaged).

While in our world today, we don't only use the grinding stone to sharpen blades and grind metal. In fact, it can be used to strip old paint and remove rust from metal works so it will be ideal for restoring vintage tools or equipment. It can also be used to smooth out rough edges on metal pieces thereby enhancing their finish. Others even grind the stone to smooth out a smooth concrete. In the age of DIYs, everyone has come to realise that their toolbox is never full without a grinding stone. This helps them to do multiple tasks at home or in their workshops more effectively.

Every client has their own specific requirements. We provide bespoke and customized grinding wheels that are specifically designed for each requirements. We work closely with our customers to develop custom products that enhance their efficiency and effectiveness, while ensuring satisfaction of the customer.

REZZ is a manufacturer of grinding wheels since 2014, and we have a wealth of experience in supplying grinding wheel solutions. We provide a broad range of custom Diamond CBN grinding wheel services which help our industrial and manufacturing customers develop higher quality products and reduce their operating cost.

We're committed to delivering the highest quality products and outstanding service. We implement rigorous quality control methods to make sure that each and every one of our grinding wheels is in line with industry standards. This provides our customers with peace of mind and reassurance. Our customer service team will be available at all times to assist and ensure that you have a smooth journey from order to delivery.

Our research and development team is always exploring new materials and processes to ensure that we remain at the forefront of the abrasives market. We put a lot of emphasis on the performance and sustainability of our products as well as offering high-quality grinding solutions to keep up with the needs of our customers. We are here to help you achieve accuracy, quality, and innovativeness in all grinding applications.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy