Diamond grinding wheels are crucial equipment that aid us in processing and refining challenging components, including metallic and stone surfaces. Much like any tool, though, they must be properly cared for to function well and last for a long time. The best methods for caring for them are through a process known as dressing your diamond grinding wheels. Dressing helps to maintain the health of the wheels as well.

Dressing diamond grinding wheels entails removing foreign materials — dirt, debris, and remaining pieces — from the surface of the wheel. And this is very important, if the wheel is dirty, it will not work as ideally. It also ensures that the diamond components of the wheel are all sharp enough to properly slice through the harsh materials. If the wheels are in good shape, you will achieve better results in your tasks!

If you enter one the dresser is very essential such as it should be fitted with your diamond grinding wheel. It is then that you need to clamp the dresser onto your workspace. After everything is prepared, you are able to move the grinding wheel over the dresser. This process helps to lift away dirt and particulates that's accumulated on the face.

However, in the case of using an abrasive stick, you have to press the stick steady on the cutting edge of the grinding wheel. Gently move the stick back and forth across the wheel surface. This method requires a bit more skill and caution so be careful and just don't ruin the wheel while you work.

After cleaning the wheel, you must ensure that the diamond parts of the wheel are evenly exposed. To do this, examine the grinding wheel surface closely. You will want to have an even and consistent spread of diamond particles. If you see any places are uneven use the abrasive stick or dresser again to resolve the surface until it appear nice and periodically.

Regularly dressing your wheels will not only improve performance but it will also prolong their lifespan. In the long run, this means that you wont have to purchase new wheels as frequently, thus saving you some money. If you are grinding anything that is delicate, a good wheel configuration will help minimize the chance to break or chip your stock.

There are some common mistakes that you need to avoid when dressing your diamond grinding wheels. Using the wrong dresser for the wheel you’re working on is one of the largest mistakes. A wrong dresser can damage the wheel and reduce its ability to grind and cut. It could even lead to a broken wheel, which would be an expensive faux pas.

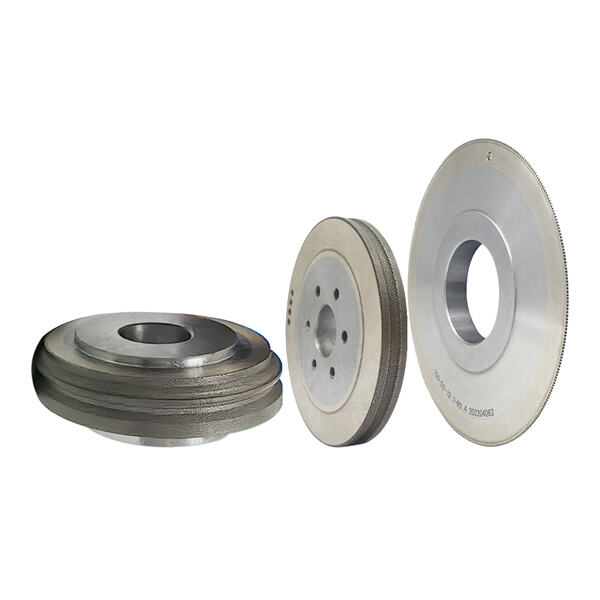

REZZ has been a grinding wheel maker since 2014, and we have plenty of experience in providing solutions for grinding wheels. We offer a wide range of customized Diamond CBN grinding wheel services that help our manufacturing and industrial customers design better products while reducing their operational cost.

Our research and development team is constantly investigating new processes and materials to ensure we stay at the leading edge of the abrasives industry. With a particular focus on performance and sustainability, we strive to provide efficient, reliable grinding solutions that meet the demands of changing customers. We are your trusted partner for accuracy, innovation and top-quality grinding processes.

We're committed to providing the highest quality products and exceptional service. We employ rigorous quality control methods to make sure that every grinding wheel is at par with the highest standards of industry. Our customers are provided with peace of mind and reliability. Our customer service team will be available at all times to assist in ensuring seamless service from the moment you place your order until delivery.

Each client has specific needs. We provide bespoke and customized grinding wheels specifically tailored to the needs. We collaborate closely with our customers to create custom products that improve their operational efficiency and put the customer's satisfaction first.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy