Abrasive wheels are vital tools used by people for grinding, polishing and cutting almost every material you can think of. They smooth over surfaces and can create cuts through hard materials. But not all abrasive wheels are created equal. They come in various types, and every kind is more suitable for specific jobs and tasks. Types and what to use it forKnowing when and which type to use.

The correct abrasive wheel is vital to your work — simply put, choosing the right one can make or break the result. Correct wheel, correct work → easier and effective work. REZZ has different varieties of abrasive wheels available, following are few common types:

Bonded Abrasive wheels: These types are the ones we see the most on an everyday basis. They are composed of fine-sized abrasive grains that are mixed with a hard material to bind them together during the manufacturing process known as a bonding matrix. This makes these wheels extremely versatile as they can be used for multiple tasks. A jack of all trades, they are adequate for most general grinding and cutting applications.

Coated abrasive wheels — Coated abrasive wheels are made by adhering the particles to a paper or fabric backing. The coating allows them to be used for sanding and polishing. These tools are adaptable and can maneuver into various forms and sizes, making them excellent for details on many materials.

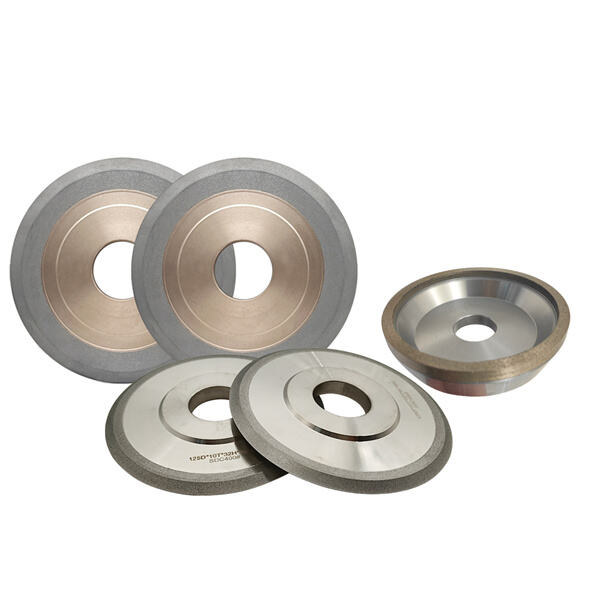

These wheels are unique in that they consist of diamond particles attached to a metal wheel. Since diamonds are among the hardest substances available on Earth, these wheels are ideal for grinding very hard materials such as concrete, glass, ceramics or even gemstones. They deliver quite accurate and clean cuts, which can be useful in tons of scenarios.

3) Non-woven abrasive wheels: They are manufactured by meeting together an amalgamation of abrasive material with a synthetic fiber material. This makes them ideal for cleansing, polishing, and prepping before other work is applied. They assist in eliminating small imperfections before providing a shinny, sleek surface.

If you pick the wrong abrasive wheel, it can actually become problematic. It may not always work properly, which can leave you feeling like an idiot. Even more important, using the wrong type can be hazardous and may result in injury or equipment damage.

REZZ is a grinding wheel maker since 2014 and we have a lot of experience providing grinding wheel solutions. We provide a variety of custom Diamond CBN grinding wheel services that help our industrial and manufacturing customers create better quality products while reducing their operational cost.

We're committed to delivering high-end quality products and excellent service. Our stringent quality control procedures ensure that every grinding wheel meets the highest industry standards, providing our customers with trust and assurance. Our customer service staff is ready to help and provide a seamless ordering-to-delivery experience.

Every client has their own specific requirements. So, we provide customizable and personalized grinding wheel solutions that are tailored to specific requirements. Collaborating closely with clients to develop custom products that enhance their effectiveness in operation, focusing on satisfaction of the customer.

Our committed research and development team constantly investigates new materials and processes, positioning us at the top of the market for abrasives. With a strong emphasis on sustainability and performance We strive to offer solid, effective grinding solutions that satisfy the ever-changing demands of our customers. We are your partner in accuracy, innovation and top-quality grinding tasks.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy