A specific tool called an diamond grinding wheel cup is used for cutting, grinding, and polishing a variety of materials. Such materials can be hard materials such as metals, woods, plastics among others. There are a few different forms of abrasive wheels, and a lot of various designs. There are specific jobs that call for each type and knowing them is crucial. This guide covers the following: what abrasive wheels are, safety precautions with abrasive wheels, types of wheels and their applications, choosing the correct wheel for your application, common issues when using abrasive wheels and how to mitigate them.

Use Safety Equipment: Always wear protective eyewear to protect your eyes. Don't forget to use gloves — that is obviously to protect your hands as well — a mask, so you won't inhale dust and debris flying in your face.

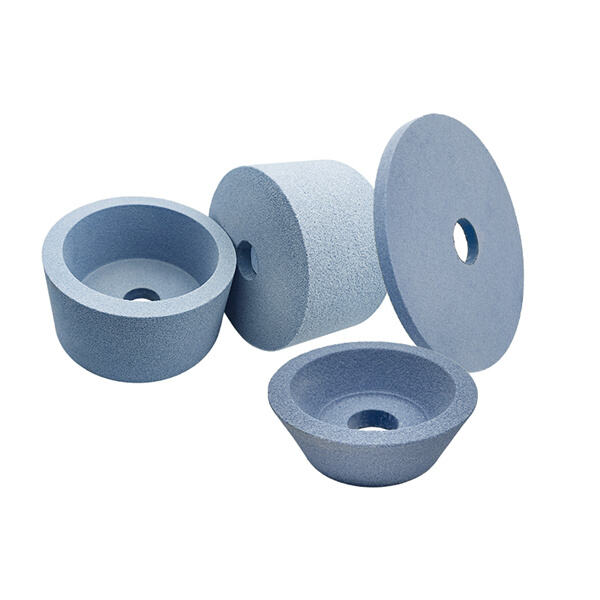

There are different types of grinder disc diamonds ( photo) and they are specialized to carry out different jobs. Understanding these types allows you to hat the one best fitted for your task. Following are some of the most commonly used abrasives wheels and their applications:

WHEEL BROKEN — The wheel can break sometimes. If used harshly, or if you exert too much pressure on it, this can happen. In that event, you have to remove the damaged wheel and install the right one and be sure it is locked properly.

Bouncing Of Wheel: If the wheel begins to bounce, it is probably out of balance or you are using excessive pressure. In order to avoid that, check for any damages on the wheel regularly and also apply pressure carefully when using it.

Glazing of a wheel: If you see the glazing of your wheel and that Is caused by overloading or because its dull. To be prudent, as far as avoid this try to reduce how much you pushing/pressing wheel with tool on it, do frequent dressing of the wheel and change it when dull.

Wheel Loading — This occurs when debris accumulates on the wheel and renders it ineffectual. Use the right wheel for the job, clean it frequently and dress it when required to ensure proper functionality.

Our research and development team is constantly exploring new materials and processes to ensure that we remain at the top of the industry in abrasives. With a keen focus on sustainability and performance we are committed to providing high-quality, efficient grinding solutions that satisfy the changing demands of our customers. We are your trusted partner for excellence, innovation, and high-quality in all grinding tasks.

We're committed to delivering the highest quality products and outstanding service. We implement rigorous quality control methods to make sure that each and every one of our grinding wheels is in line with industry standards. This provides our customers with peace of mind and reassurance. Our customer service team will be available at all times to assist and ensure that you have a smooth journey from order to delivery.

Every client has their own specific requirements. We offer a variety of customizable and customized grinding wheel solutions specifically designed for specific requirements. Working closely with our clients to develop custom products that enhance the efficiency of their operations, and focusing on satisfaction of the customer.

REZZ is a grinding wheel maker since 2014 and we have a lot of experience providing grinding wheel solutions. We provide a variety of custom Diamond CBN grinding wheel services that help our industrial and manufacturing customers create better quality products while reducing their operational cost.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy