Када је у питању брзо трошење и прецизно обрада, одабир правилног абразивног точка је од суштинског значаја. Два најчешћа материјала у овој области су дијамант и CBN . Иако су оба супер-абразивна, сваки има своје јединствене карактеристике, због чега су погодни за разне индустрије. Познавање основних разлика у њиховој тврдоћи, отпорности на хабање и утицају на прецизност обраде је од суштинског значаја да бисте повећали ефикасност ваших производних процеса. Као професионални произвођач, компанија Zhengzhou Ruizuan Diamond Tool Co., Ltd жели да вам пружи још корисније информације и производе високог квалитета у складу са вашим захтевима.

Тврдоћа материјала и прикладност примене

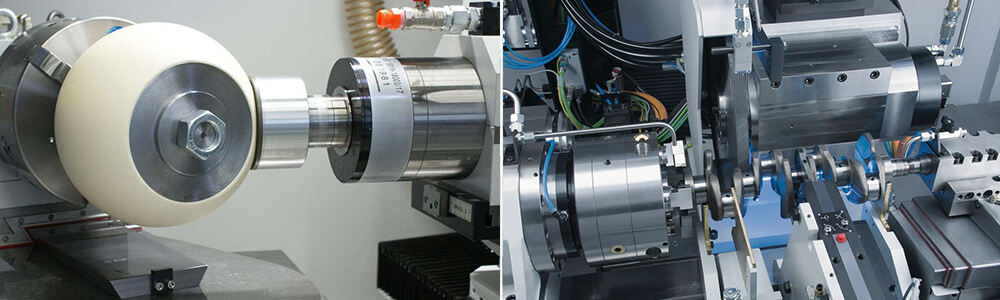

Dijamant i CBN ploče imaju jednostavnu razliku koja se zasniva na prirodnoj tvrdoći materijala. Dijamant je najtvrđi materijal na svetu. Ova tvrdoća čini dijamante idealnim za brušenje tvrdih i krhkih materijala kao što su staklo, keramika, kvarc, posuđe i poluprovodnički materijali. Oni su prvi izbor kod tvrdih legura poput volframa, silicijuma, tvrdih metala ili čelika koji postaju znatno abrazivniji na višim brzinama. Mogu se koristiti za efikasno brušenje teško obradivih materijala jer dijamantski zrnca imaju izuzetno oštre ivice.

Kubni boron nitrid je, s druge strane, drugi najtvrđi materijal na svetu; ustupajući mesto jedino dijamantu. Njegova najveća prednost je, međutim, hemijska stabilnost pri kontaktu sa gvožđem. Iako je dijamant tvrd, on može hemijski reagovati sa gvožđem u temperaturnom opsegu od 900–1300 °C (na atmosferskom pritisku), stvarajući sloj gvožđevog karbida koji ima zapreminu veću više od šest puta od originalne. To rezultuje izuzetno kratkim vekom trajanja dijamantskog tanjira pri sečenju čelika. Upravo zato CBN tanjiri daju najbolje rezultate. Posebno su formulisani za brušenje tvrdih gvozdenih metala, kao što su nerđajući i alatni čelici, kalupi i čelici za kalupe, liveno gvožđe (sivo i žilavo), visoko-legirani gvozdeni metali poput nikl baziranih superlegura, a ništa manje i egzotični metali. Tvrdoća CBN omogućava da se isti ovi otporni materijali mogu obradjivati, a da pri tome otpore habanju koje se javlja kod brušenja dijamantom.

Otpornost na habanje i dužina veka alata

Dugovečnost alata i operativni troškovi u velikoj su vezi sa otpornošću na habanje, što je direktno posledica čvrstoće i hemijske stabilnosti. Dijamantski točkovi obezbeđuju izuzetnu otpornost na habanje ako se koriste na odgovarajućim ne-gvozdenim materijalima. Karakteristike zadržavanja oblika znače da možete očekivati dug vek trajanja i maksimalne performanse, što povećava vašu produktivnost u operacijama poput brušenja tvrdih metala, brušenja keramičkih komponenti, brušenja stakla i kvarcа, kao i drugih primena.

У обради гвоздених метала, точиови са CBN-ом обезбеђују најбољу отпорност на хабање и конзистентно квалитет у индустрији. Пошто нису хемијски реактивни са гвожђем, абразивни зрна се не распадају тако лако, због чега су ови точићи погоднији за дужи век трајања и мање хабање. Резултат је још дужи век трајања точка — више од 50% дужи у односу на точиће од алуминијум оксида приликом брусења чврстих челика. Точак задржава свој облик током времена, што елиминише простоје за подешавање и замену, омогућавајући импресивну ефикасност приликом брусења великих серија делова. За процес који користи компоненте од закалjenог челика, дужи век трајања точка значи већу ефикасност и нижу цену по делу, када купујете CBN точиће од поверења достојне компаније као што је Zhengzhou Ruizuan Diamond Tool Co., Ltd.

Постизање веома високе тачности и добре квалитете површине

Циљ коришћења супер абразивних точкова је постизање максималне прецизности и завршне обраде. Оно што је важно овде је одлука између дијаманта и CBN-а. Точкови од дијаманта су толико издржљиви да могу обрадити чак и најтврђе и најтеже материјале, укључујући карбид волфрама и керамику. Њихова способност да изводе процесе резања чисто и прецизно, без стварања превеликог оштећења испод површине, важна је за интегритет компонената као што су оптичко стакло и техничка керамика.

За обраду гвоздених материјала, веома се препоручује CBN. Изузетна отпорност на хабање омогућава точку да задржи тачан профил током целокупног века трајања, од првог до последњег дела, што чини точак изузетно издржљивим. Чврсти и термички полимеризовани CBN кристали стварају мање топлоте при употреби у односу на дијамант, чиме спречавају топлотно оштећење радног предмета, које може настати због прекомерног загревања и микропукотина. Ово омогућава врло добар изглед површине, висок квалитет делова и повећан век замора за готов производ. Таква прецизност је од критичног значаја у областима као што су аутомобilsка и аерокосмичка индустрија, које захтевају максималне перформансе од сваког дела.

Укратко – питање дијамантног точка у односу на CBN за брушење није у чему је бољи него који боље ради за вашу примену и материјал. Док је дијамант краљ за хемијски отпорне и крте не-гвоздене материјале, CBN нема пармеђу абразивних зрна када је у питању обрада тешких гвоздених метала! Правилна процена нивоа чврстоће, отпорности на хабање и специфичне прецизности, као и технологија балансирања, одлучујући су фактори за испуњавање ваших набавних потреба најбољим избором. Zhengzhou Ruizuan Diamond Tool Co., Ltd. примењује десетак година знања и искуства да би створила најбоље абразивно решење за све операције брушења. Избор правилног производа је само део ефикасности, квалитета и вредности коју наша фабрика производа остварује код крајњих корисника.