Når det gjelder presisjons sliping med diamant- og CBN-skråer vil du gjerne finne ut av ett av de mest grunnleggende spørsmålene ved Zhengzhou Ruizuan Diamond Tool Co., Ltd er det tørr- eller våtsliping jeg bør bruke? Begge metodene har sine egne fordeler og bruksområder. Å velge feil metode kan føre til redusert skråliv, dårligere overflatekvalitet eller til og med skader, enten ved termisk påvirkning av arbeidstykket. Dette er en viktig forskjell å huske på hvis du ønsker høyest mulig verktøy ytelse og beste resultater i operasjonene dine.

Grunnleggende om tørrslibing

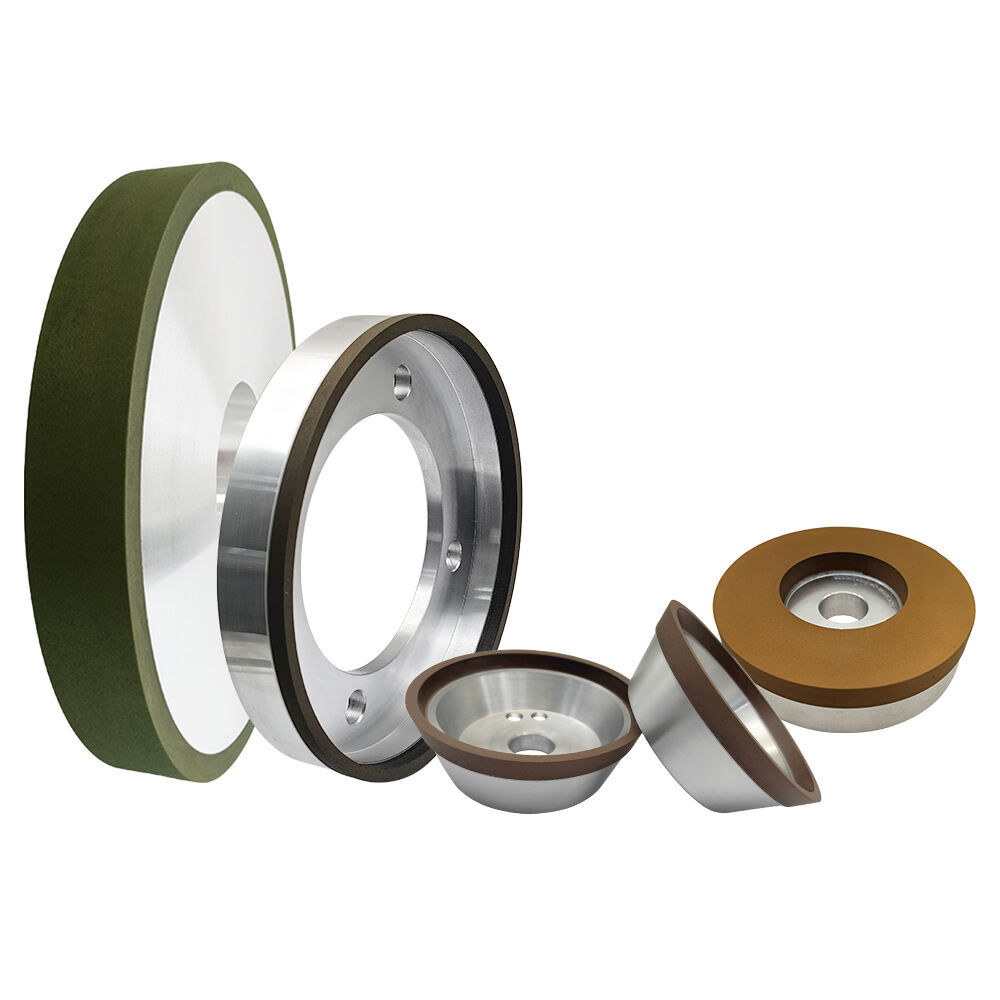

Tørrslibing er slipehjul med diamantsliper uten vannkjøling. Denne metoden velges på grunn av sin enkelhet og praktikalitet; det kreves ingen dampkjølesystem, noe som gjør konfigurasjonen mindre komplisert og mer bærbar.

Den største fordelen med tørrslibing er enkel betjening. Ingen splashing av kjølevæske betyr ingen rot, og arbeidsstykket forblir tørt, slik at umiddelbar inspeksjon eller videre operasjoner kan utføres. Dette gjør det spesielt egnet for byggeplasser, rask sliptjeneste og oppgaver der tilføyelse av et kjølesystem ikke er mulig. Med noen materialer og hjuldesign kan tørrslibing være effektiv.

Problemet med tørrslibing er imidlertid varmeutviklingen. Lokal oppvarming skapes ved friksjon mellom slipehjulet og arbeidsstykket. Uten et medium som fjerner varmen, er det stor risiko for termisk skade på arbeidsstykket, som for eksempel brening eller mikrorevner. Denne varmen kan også skade slipehjulet, og føre til at det slites ut for raskt eller glaseres over med metallspånn som dekker overflaten, noe som gjør det vanskeligere å kutte. Derfor kan det være nødvendig å bruke en lettere berøring, periodiske kutt og temperaturkontroll ved tørrslibing.

Fordelene med våtslibing

Våtslibing er når det hele tiden sprøytes kjølevæske eller smøremiddel inn i slipeområdet. Dette er den mest egnete slipeprosessen og brukes ofte som standard for industrielle applikasjoner. De fleste av denne typen produseres med hydrostatiske dobbelglidesystemer.

Kjølevæske ved våtsliping utfører tre viktige funksjoner. For det første virker den som en varmeavgiver for å fjerne den store mengden varme som oppstår gjennom friksjon. Dermed unngås skader på arbeidstykket (og diamant- eller CBN-kornene PÅ KANTEN AV slipehjulet) grunnet overoppheting av hjulet.

For det andre er kjølevæsken en smøremedium – den reduserer slipehjulets motstand mot materialet. Konsekvensen av dette er lettere sliping og dermed mindre økt slipekraft, noe som har en positiv effekt på overflaten til det slipes tykket. Væskestrømmen bidrar også til å skyve bort slipeavfall: mikroskopiske partikler av grunnmaterialet som fjernes fra arbeidstykket. Dette gjør at slipehjulet kan fungere uten å lastes opp, og holder hjulet fritt til å kutte, noe som gir mer jevne resultater fra første til siste slipeoperasjon.

Velg den riktige for din applikasjon

Så valget mellom tørr- og våtseiring er bare en smakssak. Hvis du trenger å bruke tørreseiring, vennligst velg oss, Zhengzhou Ruizuan Diamond Tool Co., Ltd, hovedsakelig for behov: praktisk og bærbar; bearbeidelsesobjektet er ikke følsomt for varme. Liten verktøyseiring, noe murerarbeid og annet feltarbeid er standard anvendelser.

For den overveldende majoriteten av presisjonsseiringsaktiviteter, spesielt med harde og sprøe materialer som herdet stål, karbid og keramikk, er våtseiring tydeligvis det bedre valget. Så lenge prioriteringen er å oppnå maksimal overflatekvalitet, holde mål og beskytte mot arbeidsstykkets brening, vil du få full nytte av et godt utformet våtseiringssystem.

Alt tatt i betraktning, avhenger hensiktsmessigheten av tørr- eller våtseving av en rekke faktorer som kan omfatte materialet ditt, ønsket overflateavslutning, osv., samt utstyret ditt. Du får maksimal ytelse og levetid av superabrasive slipekranser hvis du kombinerer dem med riktig prosess

.