These high z-shaped edges on tender metals are made via a particular process known as diamond grinding wheel cup. A carbide wheel is a high-performance tool fabricating from endure and potent compound material. That strength means that they can take a great deal of pressure and heat without failing. A machine called the grinding machine holds the carbide wheel and rotates it at very high speed. As the wheel turns, it will grind against this hard substance. This generates friction, thus (it) heats up the material surface. Because of this heat, small bits of the material are easily removed, giving us a fine edge.

Whether you are crafting an item with precision or not, carbide wheel grinding has lots of great advantages. The builds accuracy which is one of the most important advantages of these tools. It also produces edges with a great level of precision due to the carbide wheel. Such accuracy is difficult to obtain with other instruments like stones or crude plates. For many manufacturing scenarios, even a minor error can result in a product that does not function as intended. So having the right tool to make sharp edges is very important.

Carbide wheel grinding not only has this important advantage, but also it is quick and very efficient. The carbide wheel is capable of removing a quick amount of material. This quickness assists in fast tracking the manufacturing process. Reducing the time for production helps when manufacturers are creating products quickly. As a result, grinder disc diamond is ideal for the bulk production of many tools and other industrial items.

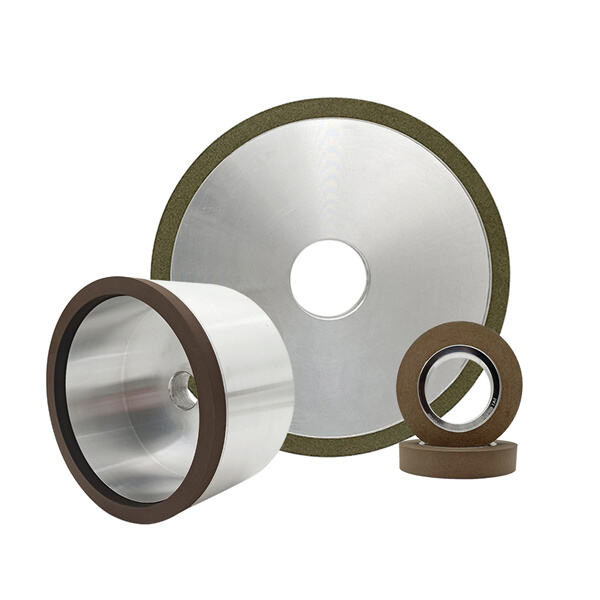

There are a few factors to consider when it comes to selecting the correct carbide wheel for your grinding jobs. Consider what sort of material you will be grinding and how hard it is initially. Various carbide wheels are used for an assortment of occupations. There are many different shapes, sizes and levels of roughness we refer to as grit. Some use a coarser grit, which removes more material quickly, while others flock toward using finer grit wheels that give you a much smoother finished edge.

Notice how useful carbide wheel grinding can be, but such tools are dangerous when you do not take the right safety precautions. Bear in mind that the protective glasses must be on throughout the process to protect your eyes from any flying object. Further, wearing a mask is advisable so that you avoid inhaling the dust particles that are harmful. Ensure that the grinding machine is firmly attached to the surface of the work. Make sure you have the carbide wheel mounted and it is tight. This prevents it from coming off when you are using the wheel.

Another important safety tip is to be sure not to bear down hard on the carbide wheel during grinding. If you press excessive force, the wheel may fall. Remember to apply only the pressure appropriate for what you are doing. Also do not apply hard or fast/rapid motion as this will tend to wear the wheel quickly and/or cause the wheel to overheat in use.

Likewise, identify the relevant wear of carbide wheels so that they are not used past their effectiveness. The wheels will work less effectively over time and may even ruin the materials you intend to grind. Replace used wheels with new identical-size, grit wheels. Making this practice will assure that you are able to maintain the level of accuracy and precision when it comes to grinding.

Our research and development team is always exploring new materials and processes to ensure that we remain at the forefront of the abrasives market. We put a lot of emphasis on the performance and sustainability of our products as well as offering high-quality grinding solutions to keep up with the needs of our customers. We are here to help you achieve accuracy, quality, and innovativeness in all grinding applications.

We're committed to delivering high-end quality products and excellent service. Our stringent quality control procedures ensure that every grinding wheel meets the highest industry standards, providing our customers with trust and assurance. Our customer service staff is ready to help and provide a seamless ordering-to-delivery experience.

REZZ is a highly experienced grinding wheel manufacturing firm that has been providing grinding wheel processing services since. We provide a range of customized Diamond CBN grinding wheel services that aid our manufacturing and industrial customers produce better-quality products and reduce their operating costs.

Each customer has unique requirements. Therefore, we offer customizable and bespoke grinding wheel solutions specifically designed for specific applications. We collaborate closely with our customers to design custom solutions that increase their operational efficiency and put the customer's satisfaction first.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy